Dry powder inhalers (DPI) have a wide range of benefits to the respiratory administration. They demonstrate a targeted effect (they do not diffuse towards inappropriate sites in the body); they achieve higher concentrations in the lungs which results in a significantly reduced drug dosage.

Furthermore, this type of administration is faster than alternatives.

In DPI, the device design, the patient inhalation manipulating have a great influencein the quantities of drug delivery. Yet, the drug’s carriers (excipients) also play a vital role in the administration of the drugs.

In order to ensure the requisite drug delivery, the flowability of the blend (mix of carriers and drug) inserted in the pill must been controlled. To increase the efficiency of the administration, two kinds of particles can be used in the formula: fine lactose particles and coarse lactose carriers.

While, the fine lactose particles enable the improvement of fine particle fraction (FPF) and the effectiveness of the administration, the coarse particles allow increased flowability of the blend during expression of the pill by the patient.

Throughout this research, consideration is given to the effects of the formulation on the flowability of the blend by an observation made that the strength interaction between fine and coarse particles are at the lowest in this system [1,2].

In order to successfully examine the development of flow properties of the blends with ageing, a new instrument was used: the Granupack. This new device allows for effective recording of a compaction curve. A powder sample is placed into a tube which is then subjected to a series of identical stresses (taps).

Prior to measuring, an initialization procedure is made in order to avoid any bias throughout the process. During the stress procedure, the volume fraction of the powder is carefully monitored in order to estimate the relevant information: a dimensionless flowability index is obtained - ranging typically from 3 (high flowability) to 30 (low flowability). Additionally, the Hausner ratio can also be calculated by using the data recorded.

Materials

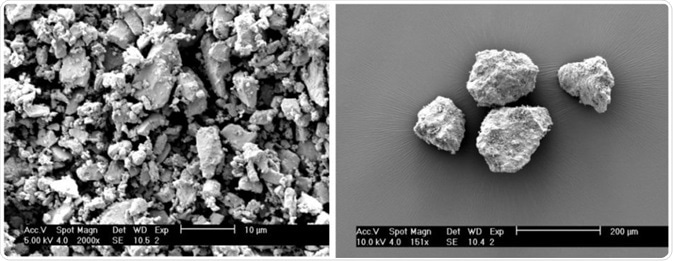

For the duration of this study, micronized lactose with a size around 2 µm and coarse lactose with a size around 120 µm were used.

Figure 1 shows micrographs of the two powders.

By mixing coarse and fine powders in different mass ratios: 90/10, 85/15, 80/20 and 75/25, four blends have been prepared. Figure 2 presents the studied blends.

Figure 1: Fine lactose (A) and coarse lactose particles (B)

Figure 2: Electron micrographs of blends prepared in agingdifferent mass ratio (coarse /fine particles): 90/10 (A), 85/15 (B), 80/20 (C) and 75/25 (D)

Results and Discussions

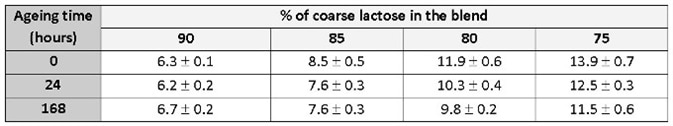

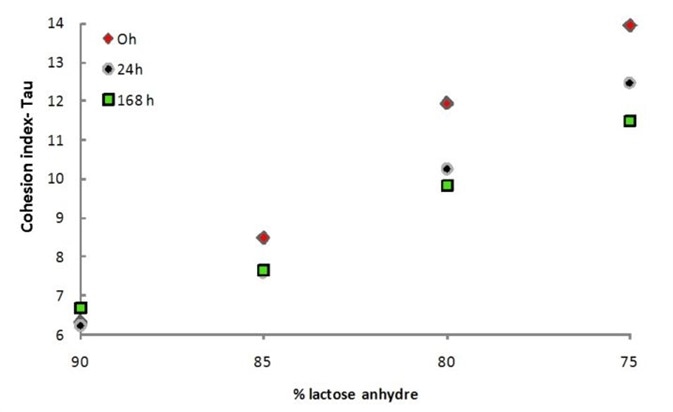

Using the Granupack instrument, the flowability of the different blends has been studied at different aging time (0 – 24 – 48 – 72 – 168h). Table 1 illustrates the flowability index and the standard deviation recorded for the powders of different ages. The p value(s) calculated from the results for an aging time varied between 0 and 24 hours are: 0.02 (75) ; 0.03 (80) ; 0.07 (85) and 0.68 (90).

As determined in the results, no significant modification in the flowability behavior can be detected for powder 90/10 – the same cannot be said for powders 75/25 and 80/20.

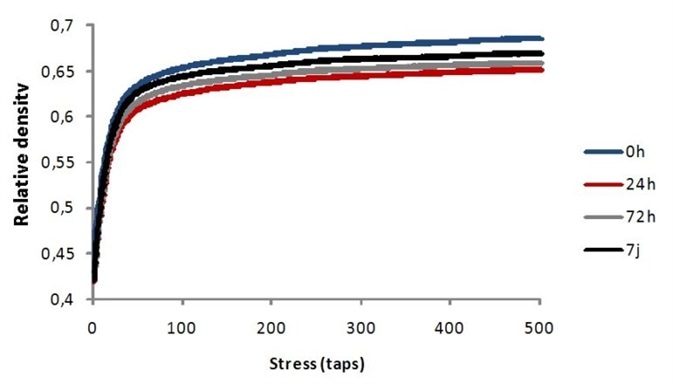

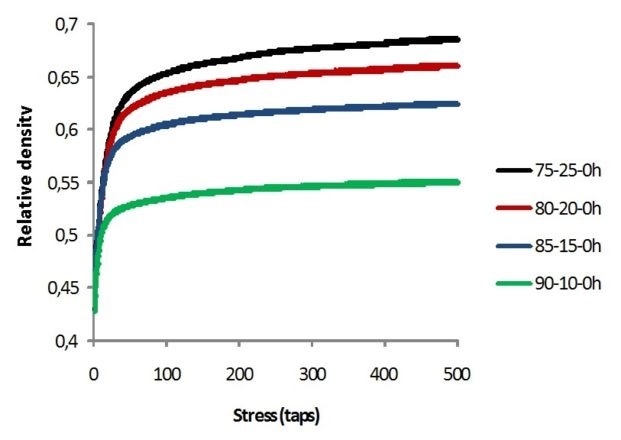

Figure 3 respectively shows the resulting tap density curves taken using the Granupack for the 75/25 blend at different aging time (figure 3A) and for different blends (figure 3B) before aging.

Table 1: Flowability index and the standard deviation recorded for the different aged powders.

Figure 3A: Tap density curves for the 75/25 blend at different aging time.

Figure 3B: Tap density curves for the different blend compositions before aging.

Looking at Figure 3B, we can discern the relevant differences between the flowability of the studied blends. In this figure, we observe that an increase of fine particles in the blend decreases the flowability of the powder. Thus, the 75/25 blend provides a higher flowability index (13.9) than the 90/10 powder (6.3).

Figure 4 highlights that the quantity of fine particles in the blend increases in line with the aging of the powder (through the flowability index).

Therefore, on the one hand, the 90/10 powder does not seem to be reliant on the aging time, while on the other the 75/25 blend is determined by a particular increase of flowability depending on the aging time (Figure 3B and 4). We should note that this improvement is particularly important during the first 24 hours.

This behavior may be due to the departure of the fine particles during the aging time because of the modification of the coarse lactose surface. This phenomenon can then explain the increase of the final density and the enhanced flowability of the blends (lower cohesion).

The collection of the fine particles localized onto the surface of the coarse particles collapses (Figure 2C) and the space between the coarse particles is taken up by the fine particles. This behavior is in good accordance with the results of previous studies realized by atomic force microscopy[1,2]. This phenomenon could be attributed to the dehydration of the fine particles directly in contact with the coarse lactose surface.

Figure 4: Evolution of the flowability index for the studied blends at different aging time.

References

- Handoko et al, Eur. J. Pharm. Sciences. 36(2009) 265-274.

- Adi Handoko et al, Pharm. Research, 23 (2006) 2556-2565.

About Granutools

GranuTools, is a company that improves powder understanding by delivering leading edge physical characterization tools.

“All we do is powder flow characterization”

A Set of Complementary Tools

Combining decades of experience in scientific instrumentation with fundamental research on powders characterization, we offer a unique set of complementary instruments for granular materials characterization.

Named after their purpose, our instruments are tools to understand macroscopic behavior of powders.

GranuFlow for flow, GranuHeap for static cohesion, GranuDrum for dynamic cohesion, GranuPack for tapped density and GranuCharge for triboelectric charge measurements are designed with the following in mind:

- Precise & Repeatable

- Automatic

- No Operator Dependency

- Robust & Easy to Use

- Clear Interpretation