Granular materials and fine powders are used across various industrial processes and applications. To optimize and control processing methods, these materials have to be characterized precisely.

Certain characterization methods are related either to the properties of the grains (morphology, granulometry, chemical composition) and to the behavior of the bulk powder (blend stability, flowability, density, electrostatic properties).

However, concerning the physical behavior of bulk powder, most of the methodologies used in R&D or quality control laboratories still rely on old measurement techniques.

During the last decade, these techniques have been modified to meet the present requirements of production departments and R&D laboratories. In particular, the measurement processes have been automatized and meticulous initialization processes have been established to obtain reproducible and interpretable results.

Moreover, new image analysis techniques vastly improve the precision of measurements.

A broad range of measurement methods have been developed to cover all the requirements of the industries processing powders and granular materials.

However, in this article, the focus will be on the GranuHeap instrument.

GranuHeap

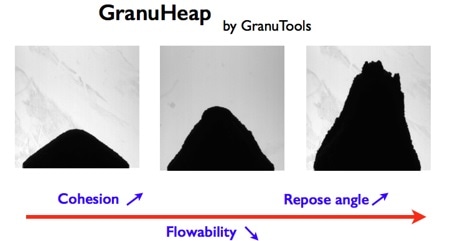

A heap can be formed by pouring a powder onto a surface. It is widely acknowledged that both the heap shape and the repose angle are dependent on the particular grain properties. Specifically, a cohesive powder typically assumes an irregular heap while a non-cohesive powder forms a standard conical heap.

Therefore, by accurately measuring the heap shape helps provide useful and important information about the physical properties of the powder sample.

The GranuHeap instrument is an automated heap shape measurement technique fundamentally based on image processing and analysis methods. Thus, a powder heap is made atop a cylindrical support.

In order to acquire reproducible accurate results, the installation of an initialization tube with an internal diameter equal to the circular support is carried out on the support. After feeding the initialization tube by hand with a pre-determined volume of powder (typically 100 ml), the tube goes up at the constant speed.

Thus, the powder flows sufficiently from the tube to form the requisite heap on the cylindrical support. A controlled rotation of the support allows for the obtaining of different heap projections corresponding to various heap orientations.

Using a custom image recognition algorithm, it is possible to determine the position of the powder/air interface. The repose angle is representative to the angle of the isosceles triangle with a paired surface similar to that of the powder heap projected image. This isosceles triangle correlates to the ideal cohesiveness heap shape.

The repose angle is then computed for each image, i.e. for each heap orientation. Afterwards, the value is computed, and an average is turned out.

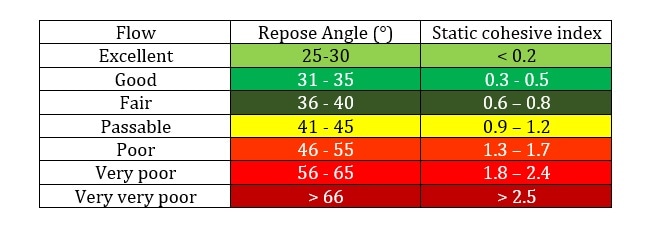

Generally, the lower the repose angle, the better the powder flowability. The aberrations between the isosceles triangular heap and the real heap interface provides the static cohesive index. The static cohesive index is computed for each image, i.e. for each heap orientation.

Thereafter, an averaged value is calculated. The static cohesive index is close to zero for a non-cohesive powder and then increases when the cohesive forces inside the powder are reinforced.

The following table summarizes the empirical relation between powder flowability and the results acquired using the GranuHeap instrument.

Experimental Setup

Material

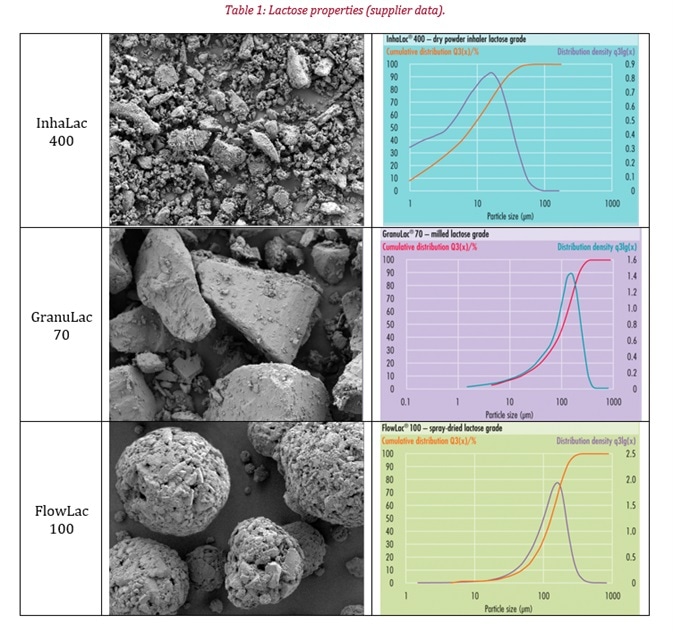

Throughout this article, three different powders were selected: GranuLac 70, FlowLac 100, and InhaLac 400. They are all lactose samples provided by Meggle Pharma.

GranuLac types comprise of sharp-edged, fine lactose particles, with cohesive powder properties that can be advantageous during granulation processes.

InhaLac is an exceptional crystalline lactose powder, designed for DPIs.

FlowLac powder is manufactured by spray-drying a suspension of fine milled alpha-lactose monohydrate crystals in a lactose solution. When lactose in solution is spray-dried, a high-speed removal of water is taking place, whereby crystalline lactose is formed in addition to amorphous, non-crystalline lactose.

Methods

For each experimental deviation with the GranuHeap instrument, the 40 / 30 / 20 and 10 mm diameter supports were selected. Sixteen pictures in all were captured during the heap rotation (1 picture each 11.25°) to allow for increased measurement accuracy. At the end of analysis, one final picture is taken to examine the integrity of the pile when measurement has been done.

All experiments were conducted under the same temperature/humidity values (30% RH and 21 °C). Each of the tests was repeated five times.

The excipients were stocked in Granutool’s laboratory over the course of several months. Therefore, the history of the samples is kept unknown and their individual properties could not correspond to the specifications of the producers for fresh powders.

Experimental Results

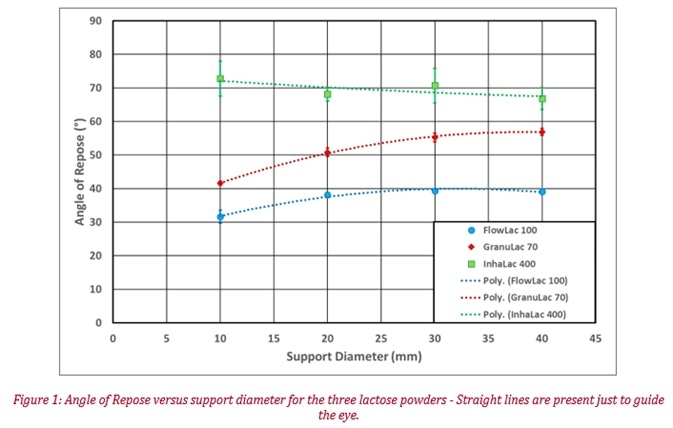

The following figure illustrates the ‘Angle of Repose’ obtained with every powder and support diameter. Straight lines do not indicate any particular model, they are just displayed to help guide the eye.

Error bars are represented (they correlate to the standard deviation on the dynamic angle of repose acquired over the five repeatability tests):

Figure 1 allows for the conclusion to be reached concerning the support influence on the static Angle of Repose measurement. Indeed, it can be seen that for powders with a ‘poor’ or inadequate flowability (Angle of Repose bellow 55°), the lower the support diameter, the lower the Angle of Repose. Nevertheless, for powders with an extremely poor flowability (Angle of Repose above 66°), there is no support influence on the results whatsoever (even if we take into account the error bars).

However, for one diameter, the trends in terms of classification of powders by flowability is the same. Thus, classification of powders can be easily achieved with greater accuracy (average error close to 3.5%). Finally, since the formation of the heap shape analysis is relative to the measurements, it allows for the conclusion that changing the heap support will not have a direct impact on the analysis.

Conclusions

The GranuHeap instrument enables the measuring of the powder flow ability with a wide range of support(s) and with a greater accuracy (average error close to 3.5% for lactose powders).

There is a small support influence to be observed on the measurements. However, for one support, the flow ability trends are the same. Therefore, classification of powders is unchanged.

Bibliography

- Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

- Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

- Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

- Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

- Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

- Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

- Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

- Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

- Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

- Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

- How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

- Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

- Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

- Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

- Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

- Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

- Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

- Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

- The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

- The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

About Granutools

GranuTools, is a company that improves powder understanding by delivering leading edge physical characterization tools.

“All we do is powder flow characterization”

A Set of Complementary Tools

Combining decades of experience in scientific instrumentation with fundamental research on powders characterization, we offer a unique set of complementary instruments for granular materials characterization.

Named after their purpose, our instruments are tools to understand macroscopic behavior of powders.

GranuFlow for flow, GranuHeap for static cohesion, GranuDrum for dynamic cohesion, GranuPack for tapped density and GranuCharge for triboelectric charge measurements are designed with the following in mind:

- Precise & Repeatable

- Automatic

- No Operator Dependency

- Robust & Easy to Use

- Clear Interpretation