Granular materials and fine powders are used across various industrial processes and applications. To optimize and control processing methods, these materials have to be characterized precisely.

Certain characterization methods are related either to the properties of the grains (morphology, granulometry, chemical composition) and to the behavior of the bulk powder (blend stability, flowability, density, electrostatic properties).

However, concerning the physical behavior of bulk powder, most of the methodologies used in R&D or quality control laboratories still rely on old measurement techniques.

During the last decade, these techniques have been modified to meet the present requirements of production departments and R&D laboratories. Particularly, the measurement processes have been automatized and meticulous initialization processes have been established to obtain reproducible and interpretable results.

Moreover, new image analysis techniques vastly improve the precision of measurements.

A broad range of measurement methods have been developed to cover all the requirements of the industries processing powders and granular materials.

However, in this article only the GranuCharge instrument will be presented.

GranuCharge

Electrostatic charges are generated inside a powder during a flow. This appearance of electric charges is due to the triboelectric effect, which is an exchange of charges at the contact between two solids.

During the flow of a powder inside a device (silo, mixer, conveyor), the triboelectric effect occurs at the contact point between the grains as well as at the contact between the grains and the device itself.

Therefore, the characteristics of the powder and the composition of the material used to build the device are crucial parameters.

The GranuCharge instrument automatically precisely measures the quantity of electrostatic charges generated inside a powder during a flow whilst in contact with a selected material. The flow of the powder sample inside a vibrating V-tube falls into a Faraday cup connected to an electrometer. The electrometer measures the charge the powder obtains during the flow inside the V-tube.

In order to acquire repeatable and reproducible results, a vibrating or rotating device is used to regularly feed the V-tube.

Selected Powders

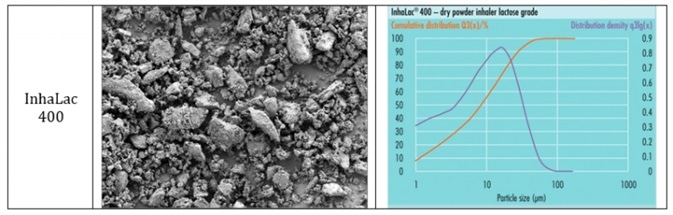

One lactose powder was selected: InhaLac 400.

This product was provided by Meggle Pharma®

InhaLac is crystalline lactose powder of high quality, designed for DPIs (Dry Powders Inhalers).

Granutools decided to study the influence of an anti-static agent in this article: Magnesium Stearate. Five different blends with a different Magnesium Stearate mass fraction: 0, 1, 3, 4 and 5% were taken into consideration.

GranuCharge Analysis

Experimental Protocol

The triboelectric effect of the powders was examined with the assistance of the GranuCharge device.

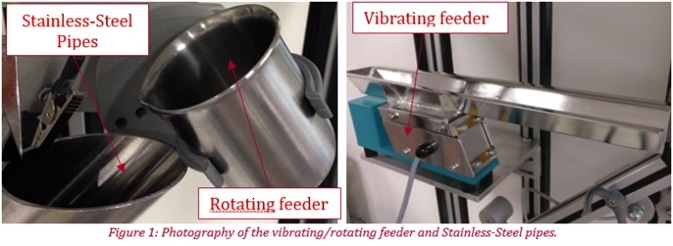

During each experiment with the GranuCharge, Stainless-Steel 316L pipes and a vibrating feeder were used:

The amount of powder used for each measurement was 20-30 g and the powder was discarded immediately after measurement. All powders were analyzed under standard conditions (43.0%RH and 21.2 °C).

At the start of the test, the initial powder charge density (qi, in nC/g) is recorded by introducing powder inside the Faraday cup.

Once completion of this step is achieved, the powder is then poured inside the rotating feeder, and then the experiment is fully initiated.

The final charge density is taken at the end of experiment (qf, nC/g).

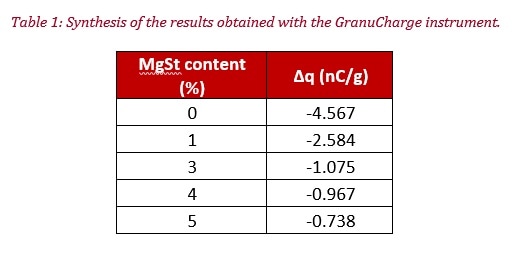

Table 1 summarizes all results acquired using the GranuCharge instrument.

The charge density variation correlates to the variance between the final charge (qf) and the initial charge (q0) densities (∆q=q_f- q_0, in nC/g):

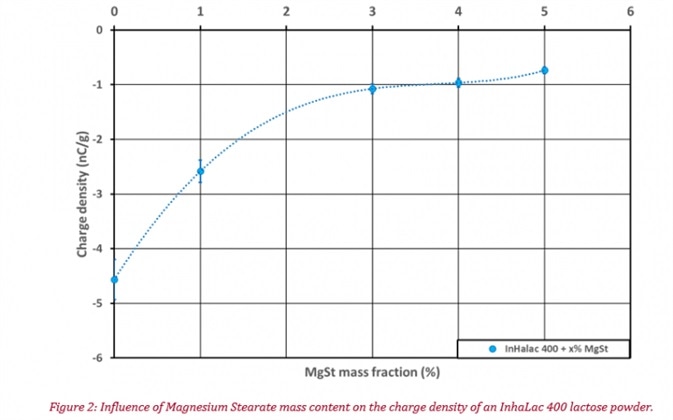

The subsequent chart is representative of the charge density variation versus the Magnesium Stearate mass fraction (in %). A straight line is observable just to guide the eye:

Results Interpretation

Figure 2 is particularly interesting because this illustration highlights the influence of the inclusion of Magnesium Stearate has on the electrical charge acquired by InhaLac 400 after a flow in direct contact with Stainless-Steel 316L pipes.

As evidenced, when only the Inhalac 400 product is used, the powder is highly sensitive to electrical charges (∆q = -4.6 nC/g).

However, when the Magnesium Stearate amount increases by mass fraction we can see a decrease in the charge density variation.

Furthermore, a Magnesium Stearate mass fraction close to 3% reaches a plateau (charge density variation close to -0.750 nC/g).

Conclusions

The influence the Magnesium Stearate addition has on the electrical charge of an Inhalac 400 product can be highlighted in a straightforward manner with the GranuCharge instrument.

With only 3% of Magnesium Stearate, electrostatic charges are limited after a flow in contact with Stainless-Steel 316 pipes.

Therefore, this instrument is decidedly sensitive, accurate (average error close to 7.8%) and it can quantify the product formulation.

Bibliography

- Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

- Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

- Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

- Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

- Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

- Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

- Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

- Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

- Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

- Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

- How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

- Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

- Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

- Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

- Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

- Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

- Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

- Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

- The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

- The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

About Granutools

GranuTools, is a company that improves powder understanding by delivering leading edge physical characterization tools.

“All we do is powder flow characterization”

A Set of Complementary Tools

Combining decades of experience in scientific instrumentation with fundamental research on powders characterization, we offer a unique set of complementary instruments for granular materials characterization.

Named after their purpose, our instruments are tools to understand macroscopic behavior of powders.

GranuFlow for flow, GranuHeap for static cohesion, GranuDrum for dynamic cohesion, GranuPack for tapped density and GranuCharge for triboelectric charge measurements are designed with the following in mind:

- Precise & Repeatable

- Automatic

- No Operator Dependency

- Robust & Easy to Use

- Clear Interpretation