Granular materials and fine powders are used across various industrial processes and applications. To optimize and control processing methods, these materials have to be characterized precisely.

Certain characterization methods are related either to the properties of the grains (morphology, granulometry, chemical composition) and to the behavior of the bulk powder (blend stability, flowability, density, electrostatic properties).

However, concerning the physical behavior of bulk powder, most of the methodologies used in R&D or quality control laboratories are still rely on old measurement techniques.

During the last decade, we have modified these techniques to meet the present requirements of production departments and R&D laboratories. Particularly, the measurement processes have been automatized and meticulous initialization processes have been established to obtain reproducible and interpretable results.

Moreover, new image analysis techniques vastly improve the precision of measurements.

A broad range of measurement methods have been developed to cover all the requirements of the industries processing powders and granular materials.

However, in this application note, we will be focused on the GranuFlow instrument.

GranuFlow

The GranuFlow is an enhanced laboratory silo compared to the outdated Hall Flow Meter (ASTM B213, ISO4490) and compared to the “Flow Through An Orifice” method described in the Pharmacopeia (USP1174).

Composed of a silo with different apertures associated with a dedicated electronic balance to measure the flowrate, the GranuFlow is an easy to use powder flowability measurement device.

This flowrate is calculated automatically from the slope of the mass temporal evolution measured with the balance. The size of the aperture can be modified quickly and easily with an original rotating system. The result analysis and measurement systems are assisted by software. The flowrate is measured for a set of aperture sizes to obtain a flow curve.

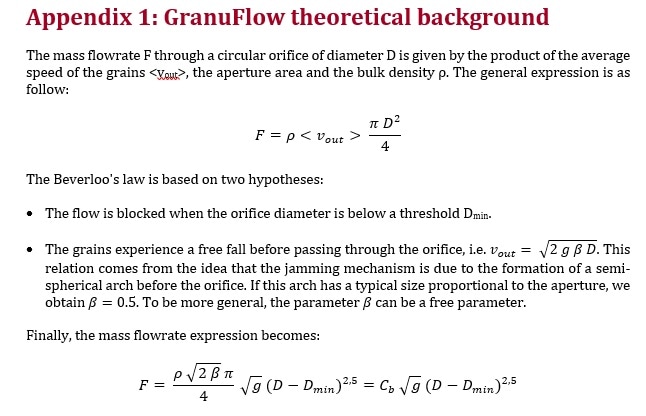

Finally, the whole flow curve is equipped with the familiar Beverloo theoretical model to acquire a flowability index (Cb, related to the powder flowability) and the minimum aperture size to obtain a flow (Dmin) (for theoretical background, user can refer to Appendix 1).

The whole measurement is performed with ease, precision, and in good time. In this study, we used a complete set of hole diameters: 4, 8, 12, 18, 22 and 28 mm.

GranuFlow Measurements

Material

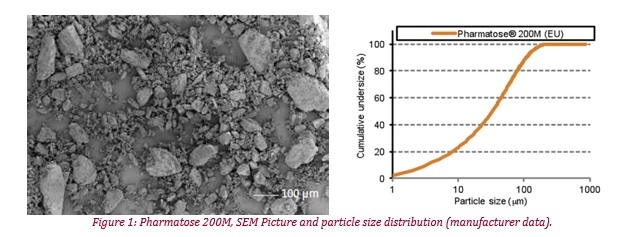

The excipient carrier used throughout this application note is known as Pharmatose 200M, provided by DFE Pharma. This is a pharmaceutical grade α-lactose monohydrate and it is milled mechanically. Due to the nature of milled lactose being fine means it has a very poor flowability, but its relatively high surface area makes it highly compactable.

Therefore, milled lactose is typically used in wet granulation applications for tablets and capsules and for spheres made by extrusion-spheronisation.

To enhance the flowing behavior of this excipient, four different flowing agents were selected for the process: Two hydrophobic amorphous silicas called Sipernat® D10 and D17 Sipernat® as well as 500LS and 50S which are hydrophilic amorphous silicas. All these products were provided by the Evonik industry.

All measurements were executed by the LRGP (Laboratoire Réactions et Génie des Procédés – University of Lorraine, Nancy, France) by Assia Saker under the guidance of Pr. Philippe Marchal and Pr. Veronique Falk.

Methods

Analysis of the GranuFlow procedures was performed at 20.7°C and 34.7%RH. The Mass Flowrate was examined for various hole sizes ranging from 4 mm to 28 mm. F is the powder flowrate (in g/s) and Cb the Beverloo parameter (in g/cm3). Dmin is the minimum aperture required size to obtain an accurate flow (for more information about the Beverloo model, please refer to Appendix 1). A mixture of 0.5, 1 and 2% of each flowing agent additive was observed in this article

Experimental Results

Firstly, it can be noted that the virgin Pharmatose 200M powder (without flowing agent) is unable to pass through any aperture. Therefore, there are no experimental results available for this sample.

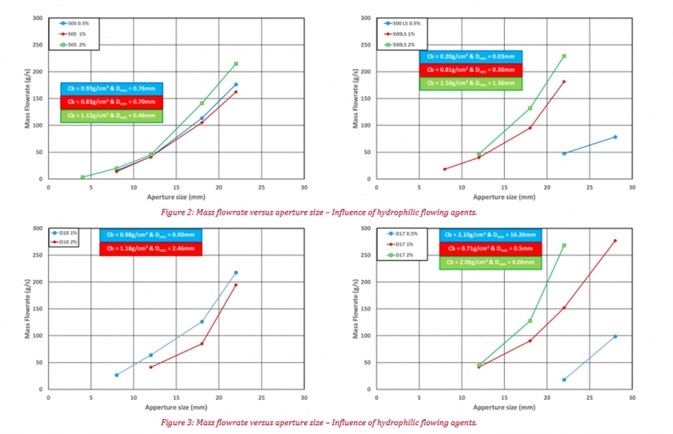

However, with the assistance of flowing agents, the flowability of blends can be measured and recorded with the GranuFlow. Corresponding Cb and Dmin parameters are also illustrated. However, for a mass fraction of 0.5% of 500 LS and D17 flowing agents, only two holes enabled the powder to flow, thus it is important to be cautious about the specified Cb and Dmin parameters. Since the Beverloo Law is a fitting model, the accurate verification of those parameters with only two points can be difficult to achieve.

Discussion

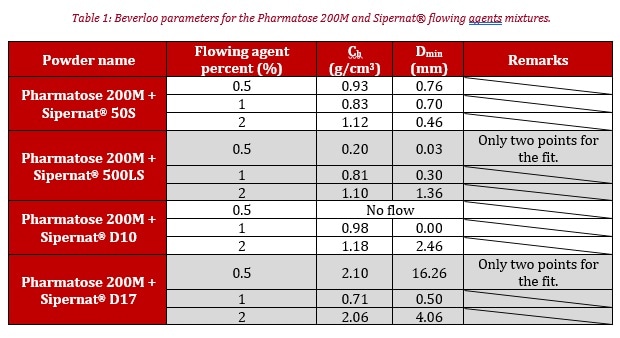

The following table summarizes all the Cb and Dmin parameters computed for the Pharmatose 200M powders with addition of flowing agents:

For Sipernat® 500 LS, D10 and D17 additions, the increase in the flowing agent percentage (until 2%), the better flowability (if the Beverloo regressions with two points are not taken into account).

However, for Pharmatose 200M with Sipernat® 50S additive, a significant flowability improvement is yielded with an additional 2% of flowing agent. Indeed, 0.5 and 1% additions add up to similar results.

Conclusions

The GranuFlow instrument has the ability to easily quantify powder flow capabilities with the inclusion and influence of flowing agents.

The mass flow rate versus the aperture size charts can serve this purpose.

As the Beverloo model fitting is available with its software, the GranuFlow can supply information on powders flowability (with the Cb parameter) and on powders cohesion (with de Dmin parameter).

All the measurements are rapid (less than five minutes for one powder, with raw data and Beverloo parameters).

Bibliography

- Cascade of granular flows for characterizing segregation, G. Lumay, F. Boschin, R. Cloots, N. Vandewalle, Powder Technology 234, 32-36 (2013).

- Combined effect of moisture and electrostatic charges on powder flow, A. Rescaglio, J. Schockmel, N. Vandewalle and G. Lumay, EPJ Web of Conferences 140, 13009 (2017).

- Compaction dynamics of a magnetized powder, G. Lumay, S. Dorbolo and N. Vandewalle, Physical Review E 80, 041302 (2009).

- Compaction of anisotropic granular materials: Experiments and simulations, G. Lumay and N. Vandewalle, Physical Review E 70, 051314 (2004).

- Compaction Dynamics of Wet Granular Assemblies, J. E. Fiscina, G. Lumay, F. Ludewig and N. Vandewalle, Physical Review Letters 105, 048001 (2010).

- Effect of an electric field on an intermittent granular flow, E. Mersch, G. Lumay, F. Boschini, and N. Vandewalle, Physical Review E 81, 041309 (2010).

- Effect of relative air humidity on the flowability of lactose powders, G. Lumay, K. Traina, F. Boschini, V. Delaval, A. Rescaglio, R. Cloots and N. Vandewalle, Journal of Drug Delivery Science and Technology 35, 207-212 (2016).

- Experimental Study of Granular Compaction Dynamics at Different Scales: Grain Mobility, Hexagonal Domains, and Packing Fraction, G. Lumay and N. Vandewalle, Physical Review Letters 95, 028002 (2005).

- Flow abilities of powders and granular materials evidenced from dynamical tap density measurement, K. Traina, R. Cloots, S. Bontempi, G. Lumay, N. Vandewalle and F. Boschini, Powder Technology, 235, 842-852 (2013).

- Flow of magnetized grains in a rotating drum, G. Lumay and N. Vandewalle, Physical Review E 82, 040301(R) (2010).

- How tribo-electric charges modify powder flowability, A. Rescaglio, J. Schockmel, F. Francqui, N. Vandewalle, and G. Lumay, Annual Transactions of The Nordic Rheology Society 25, 17-21 (2016).

- Influence of cohesives forces on the macroscopic properties of granular assemblies, G. Lumay, J. Fiscina, F. Ludewig and N. Vandewalle, AIP Conference Proceedings 1542, 995 (2013).

- Linking compaction dynamics to the flow properties of powders, G. Lumay, N. Vandewalle, C. Bodson, L. Delattre and O. Gerasimov, Applied Physics Letters 89, 093505 (2006).

- Linking flowability and granulometry of lactose powders, F. Boschini, V. Delaval, K. Traina, N. Vandewalle, and G. Lumay, International Journal of Pharmaceutics 494, 312–320 (2015).

- Measuring the flowing properties of powders and grains, G. Lumay, F. Boschini, K. Traina, S. Bontempi, J.-C. Remy, R. Cloots, and N. Vandewall, Powder Technology 224, 19-27 (2012).

- Motion of carbon nanotubes in a rotating drum: The dynamic angle of repose and a bed behavior diagram, S. L. Pirard, G. Lumay, N. Vandewalle, J-P. Pirard, Chemical Engineering Journal 146, 143-147 (2009).

- Mullite coatings on ceramic substrates: Stabilisation of Al2O3–SiO2 suspensions for spray drying of composite granules suitable for reactive plasma spraying, A. Schrijnemakers, S. André, G. Lumay, N. Vandewalle, F. Boschini, R. Cloots and B. Vertruyen, Journal of the European Ceramic Society 29, 2169–2175 (2009).

- Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants, G. Yablokova, M. Speirs, J. Van Humbeeck, J.-P. Kruth, J. Schrooten, R. Cloots, F. Boschini, G. Lumay, J. Luyten, Powder Technology 283, 199–209 (2015).

- The flow rate of granular materials through an orifice, C. Mankoc, A. Janda, R. Arévalo, J. M. Pastor, I. Zuriguel, A. Garcimartín and D. Maza, Granular Matter 9, p407–414 (2007).

- The influence of grain shape, friction and cohesion on granular compaction dynamics, N. Vandewalle, G. Lumay, O. Gerasimov and F. Ludewig, The European Physical Journal E (2007).

About Granutools

GranuTools, is a company that improves powder understanding by delivering leading edge physical characterization tools.

“All we do is powder flow characterization”

A Set of Complementary Tools

Combining decades of experience in scientific instrumentation with fundamental research on powders characterization, we offer a unique set of complementary instruments for granular materials characterization.

Named after their purpose, our instruments are tools to understand macroscopic behavior of powders.

GranuFlow for flow, GranuHeap for static cohesion, GranuDrum for dynamic cohesion, GranuPack for tapped density and GranuCharge for triboelectric charge measurements are designed with the following in mind:

- Precise & Repeatable

- Automatic

- No Operator Dependency

- Robust & Easy to Use

- Clear Interpretation