When light interacts with matter, it can undergo several processes such as reflection, transmission, absorption, or scattering. Often, these processes occur simultaneously. The extent of each process depends on the light's wavelength and the molecular properties of the material.

Raman scattering

During light scattering, the majority of scattered light undergoes no change in frequency (or energy), in a process referred to as referred to as elastic or Rayleigh scattering.

However, a small proportion of scattered light (about 1 in 106 - 107 of scattered photons) undergoes a change in frequency referred to as a Raman shift, after the physicist who first demonstrated the effect in 1927. This shift is the basis for Raman spectroscopy.

Raman spectroscopy systems accurately measure the intensity of scattered light as a function of Raman shift (a Raman spectrum), corresponding to vibrational energy changes in the constituent molecules of a substance. This results in a Raman spectrum of the material—a map of intensity versus Raman shift.

TruScan G3 Handheld Raman Analyzer. Image Credit: Thermo Fisher Scientific – Portable and Handheld Raman Spectroscopy

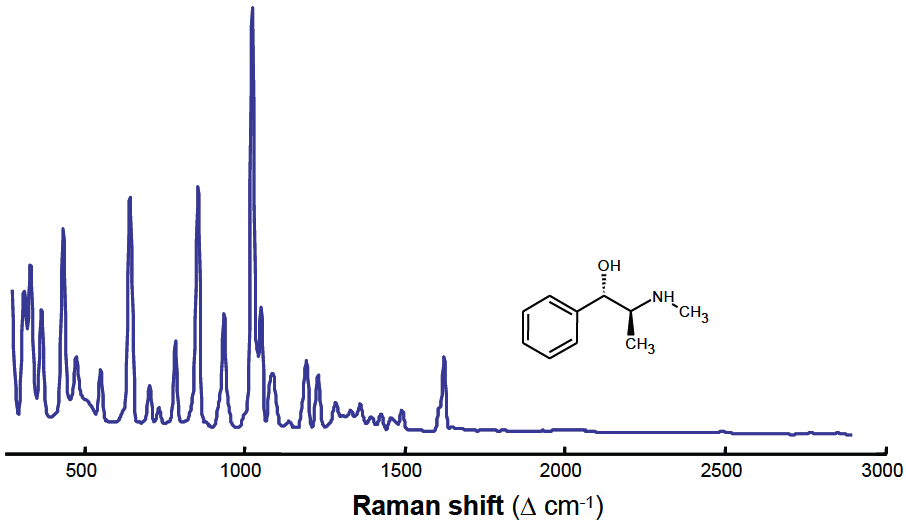

Figure 1 displays an example Raman spectrum, with intensity plotted against Raman shift in terms of wavenumber (cm-1). Individual spectral peaks correspond to vibrational transitions in the illuminated substance.

As a result, a Raman spectrum provides similar information to a Fourier-transform infrared (FTIR) spectrum. The molecular vibrational frequencies (or enegies) for a given molecule are identical in the two techniques; however, peak intensities vary between techniques, with some peaks only appearing in one spectrum.

This discrepancy arises as the two techniques depend on different physical mechanisms: FTIR is an absorption technique, while Raman is a scattering technique. Raman scattering can also be described as reflection due to molecular polarizability changes.

Figure 1. Image Credit: Thermo Fisher Scientific – Portable and Handheld Raman Spectroscopy

Instrumentation

Two primary instrumentation technologies exist for Raman spectroscopy: Fourier-transform (FT) and dispersive. The core difference between these is the analyzing technique.

In FT-Raman systems, an interferometer using and Fourier transforms is employed for spectral analysis. On the other hand, dispersive Raman systems utilize a grating spectrograph or monochromator for analysis.

The Thermo Scientific™ TruScan™ G3 Handheld Raman Analyzer makes use of dispersive technology, employing a 785 nm near-infrared laser in combination with a silicon-based charge-coupled device (CCD) detector. This configuration is lauded for its minimal fluorescence, sensitivity and ruggedness.

Analysis through blister packs enables instant field-based examination for counterfeit materials. Image Credit: Thermo Fisher Scientific – Portable and Handheld Raman Spectroscopy

Raman analysis is non-contact through polybags, plastic or glass and can measure liquids, emulsions, gels and solids in seconds. Image Credit: Thermo Fisher Scientific – Portable and Handheld Raman Spectroscopy

Applications

Raman spectroscopy is employed across various disciplines and industries, including polymers, large-molecule biopharmaceuticals, small-molecule pharmaceuticals, semiconductors, archeology, art, environmental monitoring, biotechnology, security, forensics and hazardous materials response.

Applications include counterfeit identification, raw materials quality control, material classification and verification, quantitative concentration determination and process monitoring.

Raman spectroscopy offers several advantages as an analysis technique over FTIR and near-infrared (NIR) absorption/reflectance methods. One of the most significant of which is the ability to analyze substances through plastic and glass.

Additionally, Raman spectroscopy is also able to analyze materials in aqueous solutions due to the weak Raman signal of water.

Usually, no sample preparation is required for Raman analysis, which is fast and non-destructive.

Finally, as all substances have a unique Raman spectrum, the technique is perfect for identification purposes, including counterfeit inspection and raw material verification.

Conclusion

The use of Raman spectroscopy as a quality control tool is gaining favor due to its speed, economic benefits and sensitivity due to modern laser and electronic production.

The cost of instruments has reduced from $200,000 to less than $60,000, with specialized users no longer required due to inbuilt decision-making software.

Nowadays, high-overhead laboratory space is not a necessity as instruments may be carried with one hand to a production room or receiving area.

The irrelevance of environmental humidity and the capability of Raman spectrometers to measure through containers lends the technology to compendial identity tests.

Raman technology is also ideally suited to brand security and anti-counterfeit measures throughout the supply chain.

About Thermo Fisher Scientific – Portable and Handheld Raman Spectroscopy

Thermo Fisher Scientific offers innovative solutions that help our customers solve complex analytical challenges, accelerate life sciences manufacturing, deliver medicines to market, and increase laboratory productivity. Our Thermo Scientific portable and handheld process Raman analyzers enable accurate, real-time results for process monitoring.

The Thermo Scientific™ MarqMetrix™ All-In-One Process Raman Analyzer is an all-in-one system purpose-built for rapid deployment, ease of use, and scalability in markets where time-to-results is critical. The MarqMetrix All-In-One Process Raman Analyzer is designed for:

- Analysis without sample preparation, delivering Raman spectral results in real-time

- Easy setup and deployment by non–Raman spectroscopists

- Non-destructive workflows to protect precious samples

- Non-invasive handling to minimize contamination of samples

- Small footprint for convenient deployment

- Factory calibration for hardware stability and portability

Our Thermo Scientific TruScan™ Handheld Raman Analyzers includes state-of-the-art optics paired with a patented multivariate residual analysis that offers an effective chemometric solution for material identification, with two spectral pre-processing options. The non-destructive point-and-shoot sampling principle facilitates rapid verification of a broad range of chemical compounds, including cellulose-based products.

The TruScan™ G3 Handheld Raman Analyzer continues the evolution of raw material ID testing for pharmaceutical and biotechnology manufacturing quality control processes with:

- Incoming raw material identification (RMID)

- Dispensing of materials during API manufacture

- Finished product inspection

- Identification of falsified (counterfeit) medicines

- Enables non-technical operators to rapidly perform raw material ID testing without the need of a lab

The TruScan™ RM Handheld Raman Analyzer takes pharmaceutical manufacturing QA/QC to the next level with:

- Enhanced 21 CFR Part 11 and cGMP compliance with biometric login, complex password options, and full audit trail features

- Non-contact analysis through plastic bags, glass containers, blister packs and clear gel caps

- Intuitive workflow adapted to production environment through PDF batch reports and ease of data input using barcode scanners

- Easy fleet management feature that enables cloning of instruments and identification methods

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.