For efficient operation, biopharmaceutical production needs a stream of compositional data that is nearly constant. When compared to conventional physical sampling-based measurements, the solid-state process Raman is a proven technology for gathering that data while significantly lowering maintenance and operating costs.

The composition measurements are useful for understanding a bioprocess, but ultimately, this data should be used for optimization and control.

The compositional information can be processed to achieve this goal using data science tools and packages that create reliable predictive models for crucial processes. These models can be quickly deployed to various Raman systems once they have been created and validated.

To optimize the bioprocess, the predictive models’ deployment will provide information that can be put into practice, such as when feeds or controls should be turned on.

To show how simple it is to add value with an all-in-one portable and scalable Raman system, this article will break down the straightforward process of developing and implementing quantitative Raman solutions.

Creating a model for glucose

Cells in the biopharmaceutical manufacturing process need a glucose-feeding cycle to support cell division. Modeling the glucose content of a bioprocess and predicting when to add more glucose to ensure that cells are produced at a precise rate are two functions of the Thermo Scientific™ MarqMetrix™ All-In-One Process Raman Analyzer.

Image Credit: Thermo Fisher Scientific

Global data for a global solution

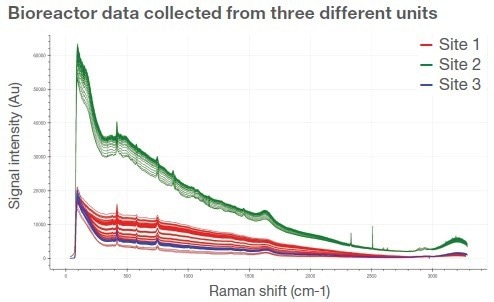

The process of gathering data is the first step in creating this model. The information displayed below is drawn from three data sets that were gathered from various processes using various MarqMetrix All-In-One Process Raman Analyzers in various parts of the world.

A robust glucose prediction model was constructed quickly. Although the combined data at first appeared to be quite disorganized, cleaning up the data and making everything work well together was easier.

Due to the MarqMetrix system’s stability and the available data science tools, this task was relatively simple. A “global” glucose model was created using the data after they had been cleaned (pretreated).

Image Credit: Thermo Fisher Scientific

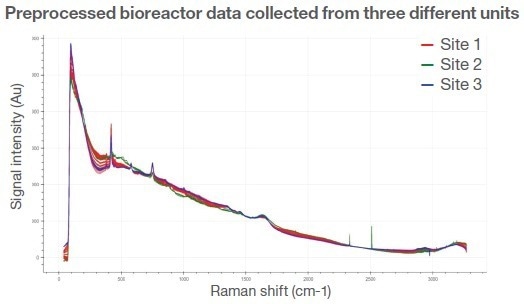

The power of preprocessing

Three key characteristics of the MarqMetrix All-In-One Process Raman Analyzer—stability, reproducible sampling interface, and factory calibration—have a significant impact on how easily data can be preprocessed. No matter where the fleet is located, these characteristics guarantee that every Raman system is incredibly accurate, stable, and consistent with other Raman systems.

From this starting point, basic preprocessing techniques can be used that pinpoint and amplify the pertinent signals in the Raman data. As a result, a predictive model was created that offers improved precision and accuracy when used with various MarqMetrix All-In-One Process Raman Analyzers.

Knowing when to feed bioprocess with data science

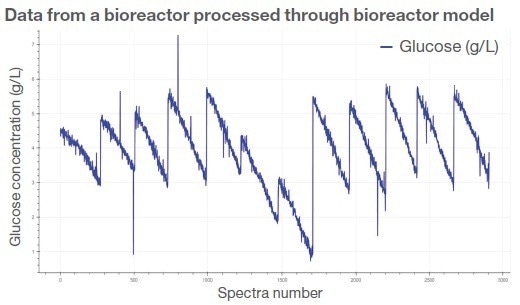

The predictive model can be used with any MarqMetrix All-In-One Process Raman Analyzer after it has been created. The glucose model was applied to data outputs from a fourth MarqMetrix system, enabling real-time monitoring of glucose concentration.

The graph below shows users where the bioprocess has been fed more glucose, as indicated by the spikes. As the glucose levels decline over time, it is necessary to feed the bioprocess to keep it in check once a minimum value is reached.

Image Credit: Thermo Fisher Scientific

Companies can take concrete actions to improve the management of their processes, thanks to the solution offered by the combination of the MarqMetrix All-In-One Process Raman Analyzer hardware and data science tools. One application where modeling can provide a useful solution is glucose monitoring.

About Thermo Fisher Scientific – Materials and Structural Analysis

Thermo Fisher Materials and Structural Analysis products give you outstanding capabilities in materials science research and development. Driving innovation and productivity, our portfolio of scientific instruments enable the design, characterization and lab-to-production scale of materials used throughout industry.

X-ray fluorescence spectrometers, FTIR spectrometers and X-ray photoelectron spectrometers enable researchers and material analysts to probe the chemical composition of materials ranging from ultra thin-films to bulk powders used in product development and materials troubleshooting. We offer a line of rheometry and viscometry instruments, as well as single- and twin-screw extruders, for laboratory benches that enable you to measure the physical property of semi-solids and liquids for shear flow and yield stress.

No other company offers the breadth of products and the depth of analytical capabilities for materials science and engineering.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.