Taylor dispersion analysis (TDA) is an orthogonal method for stability and sizing analyses of biomolecules in solution. Previous research has shown that hydrodynamic radius (Rh) measurements from TDA on monoclonal antibodies (mAbs) and other monodisperse systems are similar to data acquired using dynamic light scattering (DLS), a well-known, complementary method.

During the formulation of biopharmaceuticals, protein stability represents a major concern because it significantly affects the potency and immunogenicity of a biotherapeutic. As a result, early developability screening of candidate molecules under different formulation conditions is important. Additionally, it is essential to track the possible adverse effects of surfactants, excipients and buffer matrices on the candidate molecule, such as changes in self-association and conformational stability.

However, changes that occur in the target molecule are not always easy to observe, and this issue is further compounded by the complicated background of the excipients. In this article, TDA – a microcapillary flow-based method - is used to evaluate insulin’s stability and oligomeric state under different excipient and buffer conditions.

When assessing protein stability under formulation conditions, using the TDA method with a corresponding sample buffer makes surfactants and excipients invisible and thus allows a label-free differentiation of target biomolecules in challenging solutions. However, this is in direct contrast to light scattering measurements, where data can become increasingly governed by scattering interference from excipients present in the formulation.

Insulin is used for treating diabetes mellitus. This biotherapeutic serves as a useful case study for applying the TDA technique to the characterization of the hydrodynamic radius (Rh) to assess the stability and self-association of protein-based biopharmaceuticals found in complex solutions.

Insulin’s self-association is integral to its function in the body. The more stable form of insulin is hexameric insulin which is used to store the protein within cells, while the active form of insulin is monomeric insulin that adheres to insulin receptors. Therefore, it is important to detect insulin's oligomeric state in a particular formulation to evaluate the formulation’s stability.

When insulin monomers undergo self-association, it results in dimers which in turn join to form hexamers. It is therefore possible to view the changes in the oligomeric state of insulin via their change in size, where smaller sizes relate to oligomers of lower order. Proteins can undergo changes with variations of environmental conditions, and insulin exists in several different oligomeric states in various formulations.

In the TDA method, a nanoliter volume sample pulse is initially administered within a laminar flow of corresponding sample buffer. Upon examination of the time-evolved concentration profile from UV absorption, the molecular diffusion coefficient and thus the hydrodynamic radius of solute molecules can be easily measured.

Experimental Framework

First, insulin supplied by Sigma Aldrich was prepared in several different buffers and then filtered. Buffer was prepared using PBS, PBS + 0.18% EDTA, PBS + 0.5M urea, 0.1M HCl + 10mM NaCl. EDTA was then carried out in Miditrap columns according to GE Healthcare instructions (manufacturer) to remove zinc. TDA measurements were also conducted on a Malvern Panalytical Viscosizer at a temperature of 20°C with an uncoated capillary and a 214nm wavelength filter. Throughout the measurement process, default measurement settings for sizing were used. This was followed by DLS measurements on a Malvern Panalytical Zetasizer Nano at 20°C temperature. Solution concentrations were established with Thermo Scientific’s NanoDrop 2000.

Results and Discussion

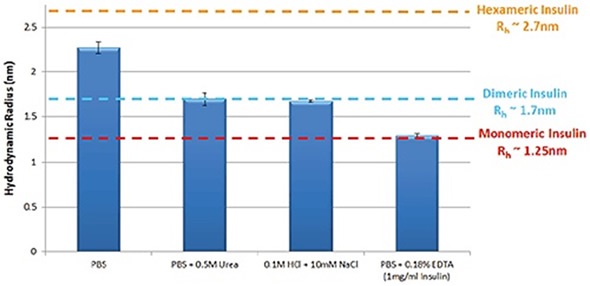

Effect of Formulation Buffer on Oligomeric State

Figure 1 displays the difference in insulin’s oligomeric state in a range of formulation buffers, as determined through the TDA technique.

Figure 1. Hydrodynamic radius of insulin measured by TDA in a range of buffer conditions. Insulin concentration is 2mg/ml (unless stated).

Improving Thermal Stability of Insulin Through the Addition of Arginine

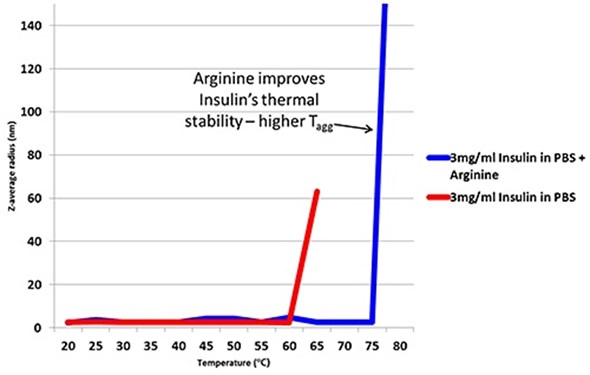

In order to enhance thermal stability, arginine, a type of excipient, was added to formulations. Figure 2 shows a thermal trend plot generated with DLS, indicating how the inclusion of arginine raises the temperature at which insulin begins to aggregate.

Figure 2. Thermal trend measured by DLS (Zetasizer Nano) showing an increased aggregation temperature for insulin in PBS with the addition of arginine.

DLS serves as a practical tool to track thermal stability. However, when attempting to follow changes in a target molecule, the excipients themselves can influence light scattering data, especially when the excipient and the target biomolecule are of identical size.

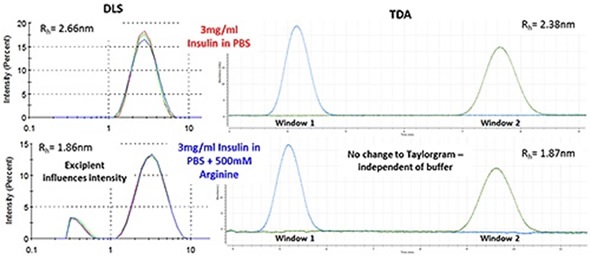

Figure 3 depicts how the arginine added to the buffer is detected as an individual intensity peak in DLS, while the TDA Taylorgram remains unaffected with the inclusion of excipients. TDA selectively tracks the preferred molecule, irrespective of formulation components. Twin window detection methodology is used by the Malvern Panalytical Viscosizer for TDA, and the dual peaks displayed in the Taylorgrams (Figure 3) are measurements derived from the same sample pulse that are isolated temporally at different detection points along the microcapillary.

Figure 3. DLS (Intensity vs size plots) and TDA Taylorgrams (UV Absorbance vs time plots) for solutions of 3mg/ml Insulin in PBS with and without the addition of arginine.

Conclusion

It is essential to understand the effect of surfactants, excipients and other formulation components on the stability and self-association of proteins in solution, because biotherapeutic products often need complicated formulations. However, the effect of complex mixtures of surfactants and excipients in the formulation matrix can impede with light scattering data; from a noticeable reduction of measurement sensitivity, especially at low concentrations of protein, through to masking the signal from the target protein molecule. In this article, the use of insulin shows how TDA can be utilized to track oligomeric state and self-association for a range of buffer conditions.

Significantly, the application of UV detection at a specific wavelength and running measurements with the corresponding sample buffer makes TDA selective for the protein molecule of interest, and makes the formulation components imperceptible in the measurement data. As an orthogonal technique, TDA is perfect for screening bio-therapeutics for early-stage developability under different formulation conditions, particularly as this automated method can be used at low concentration with very low sample volumes.

References

- A. Lavoisier, J-M Schlaeppi, ‘Early developability screen of therapeutic antibody candidates using Taylor Dispersion Analysis and UV area imaging detection’ mAbs 7:1, 77-83 (2015)

- A. Hawe, W.L. Hulse, W. Jiskoot, R.T. Forbes, ‘Taylor Dispersion Analysis compared to Dynamic Light Scattering for the size analysis of therapeutic peptides and proteins and their aggregates’ Pharm Res 28: 2302-2310 (2011)

- A.M. Gualandi-Signorini, G. Giorgi, ‘Insulin formulations – a review’ European Review for Medical and Pharmacological Sciences 5: 73-83 (2001)

- Malvern Panalytical White Paper ‘Understanding Taylor Dispersion Analysis’ www.malvern.com

- A. Ahmad, I.S. Millett, S. Doniach, V.N. Uversky, A.L. Fink, ‘Stimulation of Insulin Fibrillation by Urea-induced Intermediates’ Journal of Biological Chemistry 279: 14999-15013 (2004)

- M.M. Varughese, J. Newman, ‘Inhibitory Effects of Arginine on the Aggregation of Bovine Insulin’ Journal of Biophysics Volume 2012, Article ID 434289, 7 pages (2012)

About Malvern Panalytical

Malvern Panalytical provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems.

These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries.

Used at all stages of research, development and manufacturing, Malvern Panalytical’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.