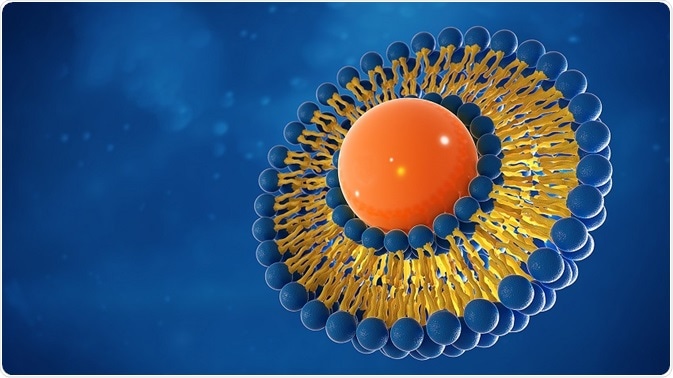

Liposomes have long been an attractive delivery system. They are composed of natural biological lipids and structurally resemble cell membranes. They are metabolically compatible, low in toxicity, have overall expectations of biocompatibility and lack a strong immune response [1]. Frequently classified by size, polydispersity, and number of bilayers, liposomes comprise spherical vesicles with an aqueous core. These are enclosed by at least one phospholipid bilayer or lamellae [2].

Image Credits: Luminancestudio/shutterstock.com

A challenge that remains with most preparation methods is control over the size, polydispersity, and number of bilayers. This is amplified even further when moving from a laboratory to industrial scale. Between 50 and 200 nm is a desirable size for drug delivery [3]. Studies modeling biological membranes, phase transition and spacing, and targeted drug delivery are all examples of where liposomes are used [4].

The relative concentrations, size and lamellarity, lipid composition and incubation temperatures all affect the extent of liposome instability [1]. It is therefore critical to biophysically characterize these systems and their payloads to understand and optimize their fabrication and function.

This article examines the most favorable conditions for extruding liposomes along with their stability under varying conditions. The limit of detection for fluorescently labeled liposomes is also highlighted. Malvern Panalytical offers a cost-effective solution for direct characterization of these crucial parameters.

Size, concentration and fluorescence can all be measured with the Nanoparticle tracking analysis (NTA) from the NanoSight product range. Within the Zetasizer product range are dynamic (DLS) and electrophoretic (ELS) light scattering which measure size, zeta potential, and payload stability. Determination of the lamellarity, structures, and dimensions of the lipid bilayers are enabled through small- and wide-angle X-ray scattering (SAXS/WAXS).

References and Further Reading

[1] Woodle M.C., Advanced Drug Delivery Reviews 16 (1995) 249-265

[2] Patil Y.P., Jadhav S., Chemistry and Physics of Lipids 177 (2014) 8-18

[3] Harashima H., Sakata K., Funato K., Kiwada H., Pharmaceutical Research 11 (1994) 402-406

[4] Chibowski E., Szczes A., Adsorption 22 (2016) 755-765

About Malvern Panalytical

Malvern Panalytical provides the materials and biophysical characterization technology and expertise that enable scientists and engineers to understand and control the properties of dispersed systems.

These systems range from proteins and polymers in solution, particle and nanoparticle suspensions and emulsions, through to sprays and aerosols, industrial bulk powders and high concentration slurries.

Used at all stages of research, development and manufacturing, Malvern Panalytical’s materials characterization instruments provide critical information that helps accelerate research and product development, enhance and maintain product quality and optimize process efficiency.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.