The new revision of the European Pharmacopoeia chapter on Water for Injection (WFI) now allows the generation of WFI by utilizing Reverse Osmosis1 (RO), paving the way for companies to decrease their carbon footprint and energy bills by moving away from using stills.

This article outlines the growing focus on Total Organic Carbon (TOC) and conductivity measurement, particularly for companies looking to utilize RO water treatment plants to produce WFI, and supplies best-practice advice for calibration.

Background

The European Directorate adopted their new pharmacopoeia chapter on Water for Injection (WFI) in March 2016 after consultation with a working group of experts from the pharmaceutical industry.

In this new chapter, WFI production from reverse osmosis (RO) is permitted, as long as the water quality is equivalent to that produced by a still, whereas the previous form of this chapter instructed that WFI should be created from a still.

Yet, concerns were raised as to the robustness of RO compared to stills and the potential for biofilm build up, microbial break-through, or for contamination from microbial bi-products, during the consultation period.

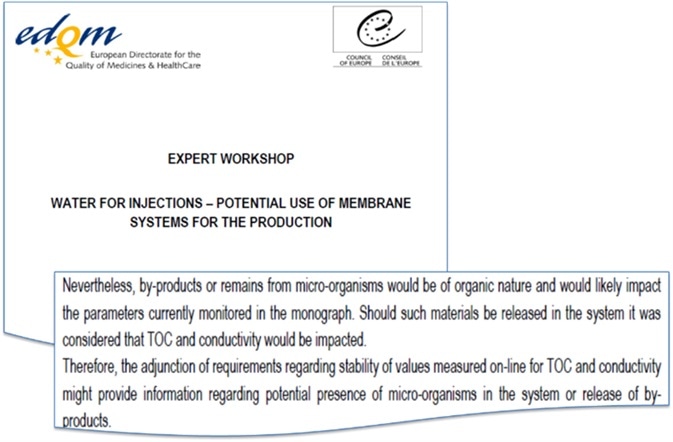

During the EDQM Expert Workshop2, the heightened importance of monitoring for conductivity and TOC were emphasised as indicators of potential microbial contamination or from microbial by-products.

TOC and conductivity

TOC analysis is a non-specific test, which means it is simply a measure of the carbon found in any organic compound in the water, it is not able to indicate the type of organic molecule present.

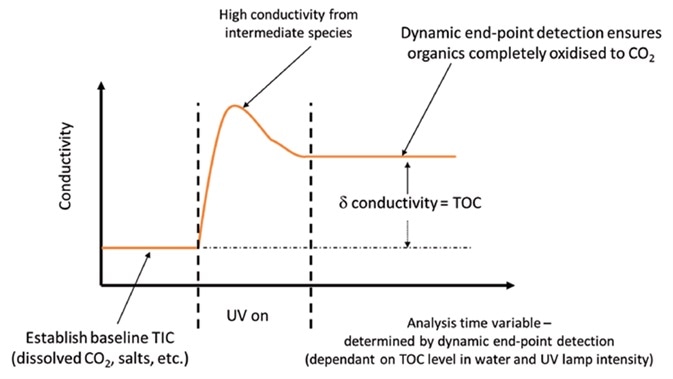

A pharmaceutical-grade TOC analyzer utilizes ultraviolet light (UV) to oxidize the organic molecules to release the carbon atoms present and then measures the difference in water conductivity due to the resultant carbon dioxide.

By measuring Total Inorganic Carbon (TIC) and Total Carbon (TC) and subtracting one from the other, TOC is calculated.

TC - TIC = TOC

Figure 1. TIC and TC are measured and TOC is calculated.

The European Pharmacopoeia chapter on TOC for PW and WFI, EP 2.2.44, calls for total oxidation of the organic molecule for accurate TOC analysis, so if some of the carbon atoms remain bound into the organic molecule and are not oxidized, then the TOC analyzer would under-report TOC as they would not be measured.

It is for this reason that it is crucial the TOC analyzer can detect when oxidation is finished before reporting TOC levels. TOC results are reported in Parts Per Billion (ppb) which in this case is the mass (weight) of organic carbon per litre of water.

Longer-chain complex organic molecules will possess more carbon atoms than short-chain organic molecules, so the equivalent amounts of the long- and short-chain molecules will be reported differently by the TOC analyzer, with reported TOC from the long-chain organics giving higher TOC results.

TOC analyzers which utilize conductivity to measure the organic carbon can also be employed to detect inorganic contamination. Yet, the pharmacopoeias are extremely specific regarding calibration of conductivity analyzers and the TOC analyzer would have to fully comply with their needs.

USP<645> is very clear that it is necessary for the conductivity meter cell constant to be verified against a certified conductivity solution and that the meter electronics must be verified by the utilization of a certified calibration resistor.

Figure 2. Organic molecule sucrose contains 12 carbon atoms. Image Credit: Beckman Coulter Life Sciences

Importance of TOC and conductivity with the new EP vhapter on WFI

The Working Party who supported the European Directorate warned that RO water treatment might not be as robust as a still and stressed the role of TOC and Conductivity analyzers as early detectors of potential impending endotoxin excursion or microbial events.

Figure 3. Working group supporting European Directorate emphasizes the importance of TOC and Conductivity analyzers. Image Credit: Beckman Coulter Life Sciences

A crucial sign that there is a different, more complex long-chain molecule entering the water system, or that either the quantity of organic molecules present in the water is increasing, is an increase in TOC results in a water system that normally has consistent TOC results.

These alterations in TOC results can be a sign that the integrity of the water treatment system is being threatened and could be an early warning of a potential impending microbial breech.

It is vital to capture a sample of the water at the time when the TOC increase is detected, as such events are often transient in nature, so that it may be sent to the quality control laboratory for more analysis to try and determine the root cause of the transient.

Clearly TOC and Conductivity analyzers have to be calibrated correctly and their calibration validated, to make sure that they are working properly in case an alteration in the water chemistry happens.

As such, to eradicate all of the carbon atoms, the intensity of the oxidizing UV lamp must be monitored to ensure that it is strong enough to oxidize organic molecules sufficiently.

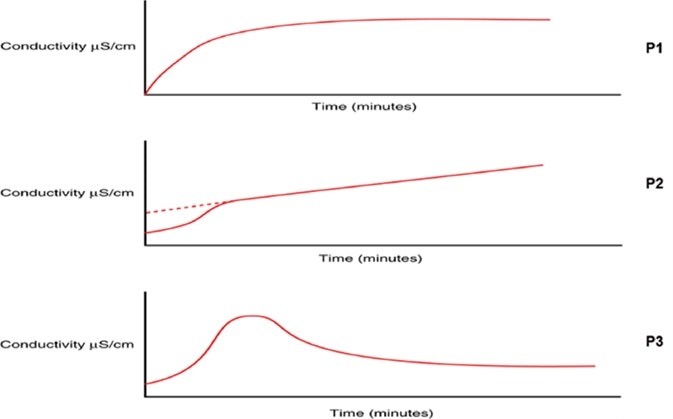

Although TOC analyzers cannot establish what the organic molecules are, they can be utilized to identify an alteration in the organic chemistry in the water as longer-chain organic molecules usually show a different oxidation profile compared to short-chain organic molecules.

If the TOC analyzer can detect a change in oxidation profile when the water organic chemistry changes, combined with a change in TOC results, this information can indicate to the user the requirement to perform an investigation to establish whether the water system integrity is becoming compromised.

TOC and conductivity analyzers: Best practices for calibration

Calibration

Usually, most pharmaceutical manufacturers have their TOC analyzers calibrated every six months. There are two types of calibration; calibration adjustment and calibration validation.

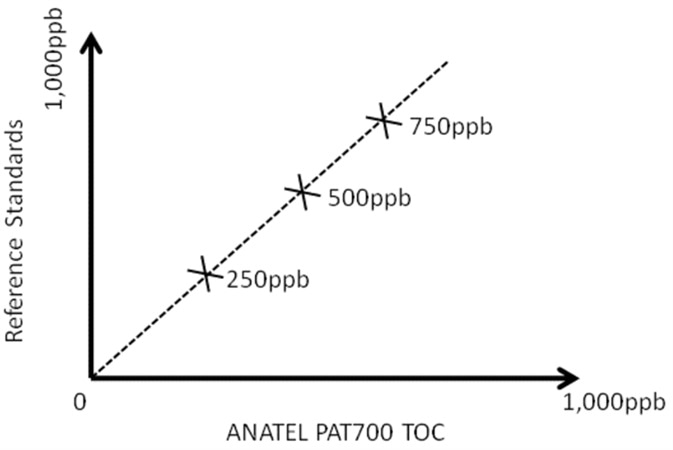

For calibration validation, certified calibration standards are performed as grab samples and the performance of the TOC analyzer is compared to the certified values. If the values reported from the TOC analyzer are inside an acceptable percentage of the certified values of the standards (blank subtracted) a ‘Pass’ is given.

Certified calibration standards are run through the TOC analyzer for calibration adjustment. The TOC analyzer changes its calibration slope to give a best fit against the certified values of the standards.

As long as the TOC analyzer can change its slope to provide a correlation coefficient (linearity factor) ≥0.990 and that the adjustment in the calibration slope of the TOC analyzer is not a big alteration from the original factory calibration, then a ‘Pass’ is given as the new calibration is considered acceptable.

An adjustment in the calibration slope which is a big change from the factory slope is thought to be a sign that something has gone wrong, i.e. either the calibration standards are not matching their certified value, or the analyzer is not working properly.

Although not mandated, it is considered best practice to perform the below step-by-step procedure when calibrating a TOC analyzer:

- Perform an ‘as found’ calibration validation prior to making any adjustments. This confirms that the TOC analyzer has been working within specification since the last calibration and that nothing has gone wrong since then.

- Perform a calibration adjustment. This ‘fine tunes’ the calibration of the TOC analyzer to protect against gradual drift in calibration over extended periods of time and make it as accurate as possible.

- Carry out an ‘as left’ calibration validation. This confirms that the calibration slope adjustment performed in step b) has led to an accurate calibration compared to certified, traceable, standards.

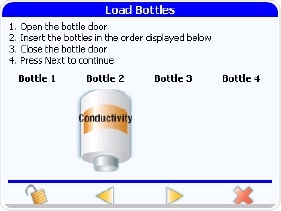

Figure 4. 'As found' calibration confirms TOC analyzer is still performing acceptably after 6 month's use. Image Credit: Beckman Coulter Life Sciences

System suitability

This test is designed to make sure that the TOC analyzer can analyze the variety of organic contaminants which could occur in PW and WFI equally. With the concerns around potential microbial contamination or from microbial by-products, this takes on a particular significance as the type of organic contamination can change with time.

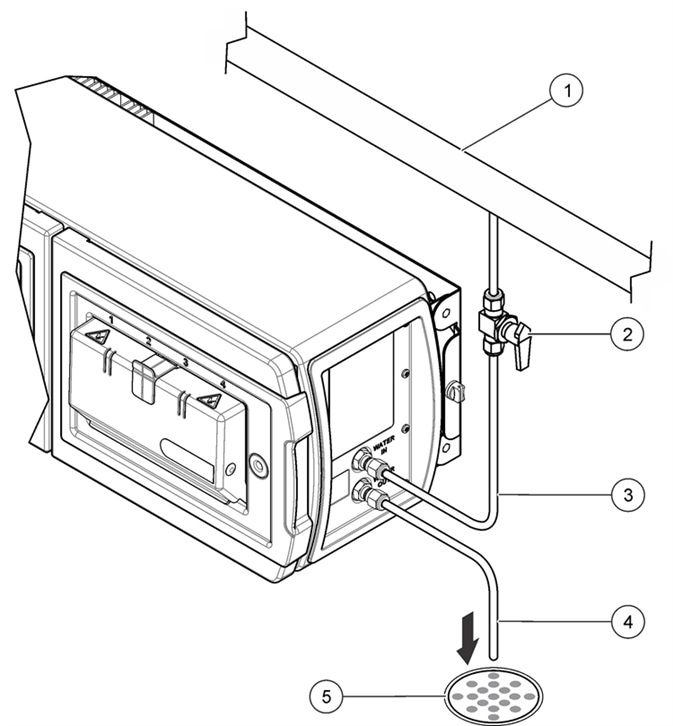

Figure 5. Calibration solution goes to drain. Image Credit: Beckman Coulter Life Sciences

Conductivity

The drawback of traditional conductivity instruments is that the measurement cell is inaccessible as it is inside the WFI pipe, so the cell constant cannot be checked as recommended in the United States and European pharmacopoeias (USP and EP)3,4 with a conductivity solution of a known, certified value.

The TOC analyzers which utilize direct conductivity measurement as part of their TOC analysis, for example the PAT700 from Beckman Coulter, are able to have the cell constant checked. This is because the sample entering the conductivity cell subsequently goes to drain and so does not compromise the water loop itself.

Figure 5a. PAT700 direct conductivity analyzer cell constant can be verified according to the requirements in USP <645>. Image Credit: Beckman Coulter Life Sciences

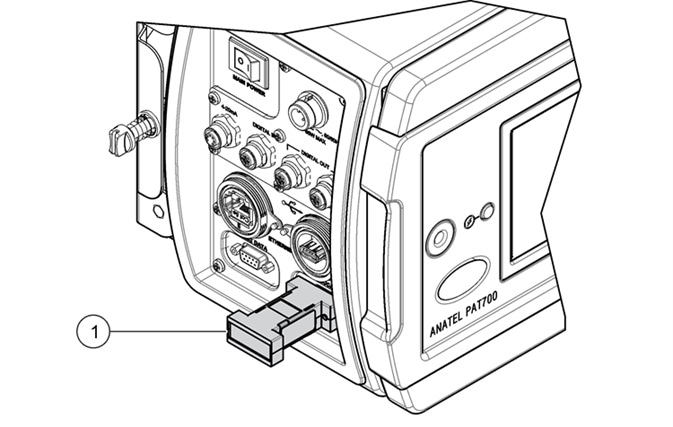

The majority of TOC analyzers are unable to comply with the USP and EP requirements to check the accuracy of the conductivity meter electronics utilizing an external resistor. The PAT700 has been specifically designed to support this requirement, satisfying all of the compliance requirements of the USP and EP as a conductivity analyzer.

Figure 6. Item 1 indicates the external calibration resistor. PAT700 direct conductivity analyzer meter accuracy can be verified using external resistor as per the requirements of USP<645>. Image Credit: Beckman Coulter Life Sciences

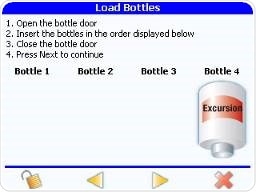

Excursion capture for root-cause analysis

Conductivity contamination or TOC events may be transient in nature. For instance, as biofilm sloughs off the inside of the pipework, a water system which is experiencing gradual biofilm build up may experience TOC excursions just after sanitization cycles.

This excursion can disappear fast, either by broken down by UV lamps connected to the pipework distribution network put in place to discourage microbial build-up, or by being diluted as it passes into the large amount of water in the loop storage tank.

Yet, this quick disappearance may mask the growing biofilm build up until there is a breakdown of system control and run-away microbial contamination. Should a TOC excursion be detected, the PAT700 can be programmed to gather a water sample so that the sample can be analyzed further to determine the root cause.

Figure 7. PAT700 can capture a water sample to support root cause analysis if a TOC excursion is detected. Image Credit: Beckman Coulter Life Sciences

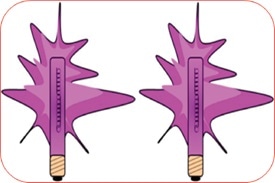

Dual UV and UV detect

UV light is the main technique which is utilized by the majority of pharmaceutical-grade TOC analyzers to oxidize the TOC. Almost all TOC analyzers which utilize UV light have only a single UV lamp and do not monitor the level of UV light the lamp emits, thus potentially ignoring a decrease in UV light output which could compromise the analyzer’s ability to measure TOC.

The general lifespan of these UV lamps is around a year and if the UV lamp fails completely, then the analyzer cannot analyze TOC anymore. The level of TOC can be <10ppb in modern WFI systems, and a failed TOC analysis UV lamp may go unnoticed, leaving potential TOC excursions in the WFI system to go undetected.

If the user detects a failure of the UV lamp it may trigger the requirement for increased grab sample TOC analysis by the QC laboratory until the TOC analyzer is able to be fixed. The PAT700 has main and standby UV lights and monitors the UV light output.

The standby lamp is automatically activated and an alarm sounds to notify the user if the UV light from the main lamp falls under an acceptable level for good TOC analysis.

Figure 8. PAT700 protects against unplanned down-time and expensive service call-outs by having auto-switching main and stand-by UV lamps. Image Credit: Beckman Coulter Life Sciences

Complete oxidation

The importance of complete oxidation of the organic contamination to attain an accurate TOC measurement is emphasized in the EP 2.2.44 chapter on TOC analysis3. In the process of being oxidized down to CO2, more complex, longer chain organic molecules may produce organic acids.

These organic acids could contribute more highly to the conductivity measurement than the final CO2 from the completely oxidized organic, so an incorrect TOC value could be gathered from the failure to ensure complete oxidation of the organic.

To detect if the organic has been completely oxidized, the PAT700 monitors the alteration in the conductivity measurement and waits until there are no more alterations, thus ensuring accurate TOC analysis.

Figure 9. PAT700 uses dynamic end-point detection to ensure complete oxidation for accurate TOC analysis, even when UV lamp intensity decreases. Image Credit: Beckman Coulter Life Sciences

TOC oxidation curve profile

Some TOC analyzers, like the ANATEL PAT700 from Beckman Coulter, give an indication of the oxidation curve profile during each TOC analysis.

A change in TOC levels combined with a change in the type of profile, could give insight into a potential degradation of the RO system integrity, prompting the user to further examine and consider corrective action to stop a large-scale contamination event and to put in place preventative measures to avoid the problem happening again in the future.

Figure 10. Changes in TOC oxidation profile curve can indicate potential degradation of water treatment integrity, prompting investigation to prevent a large-scale contamination event. Image Credit: Beckman Coulter Life Sciences

Conclusion

General purpose TOC analyzers which are designed to fit many different types of application may not supply the same level of confidence that analyzers which are specifically designed for PW and WFI analysis in the regulated GMP environment, for example the ANATEL PAT700 from Beckman Coulter.

Manufacturers who are looking to benefit from the new EP chapter permitting WFI production from RO treatment to decrease their carbon footprints and overheads may require a higher level of assurance that any slight alteration in conductivity or TOC will be detected robustly and accurately.

They may want to consider choosing a TOC and conductivity analyzer which is designed specifically for PW and WFI, instead of a general purpose TOC analyzer.

References

- European Pharmacopeia (Ph. Eur.) Commission press release 18th March 2016 www.edqm.eu/en/

- EDQM Expert Workshop, 24 March 2011 European Directorate for the Quality of Medicines & Healthcare (EDQM) 7 allée Kastner, CS 30026 F -67081 Strasbourg

- US Pharmacopeia Convention, United States Pharmacopoeia, Rockville MD, USA and Council of Europe, European Directorate for the Quality of Medicines & Healthcare, European Pharmacopoeia, Strasbourg, France

- Council of Europe, European Directorate for the Quality of Medicines & Healthcare, European Pharmacopoeia 8.0, 01/2008:20244, Total Organic Carbon in Water for Pharmaceutical Use, Strasbourg, France

- International Society for Pharmaceutical Engineering, The ISPE Good Practice Guide: Ozone Sanitization of Pharmaceutical Water Systems, First edition July 2012 http://www.ispe.org/ispe-good-practice-guides/ozone-sanitization-pharmaceutical-water-systems [14th August 2014]

- Pharmaceutical and Healthcare Sciences Society, Best Practice for Particle Monitoring in Pharmaceutical Facilities, PHSS Technical Monograph No.16, First Edition 2008, ISBN 978-1-905271-15-3

About Beckman Coulter Life Sciences

Beckman Coulter Life Sciences is dedicated to empowering discovery and scientific breakthroughs. The company’s global leadership and world-class service and support delivers sophisticated instrument systems, reagents and services to life science researchers in academic and commercial laboratories, enabling new discoveries in biology-based research and development.

A leader in centrifugation and flow cytometry, Beckman Coulter has long been an innovator in particle characterization and laboratory automation, and its products are used at the forefront of important areas of investigation, including genomics and proteomics.

Primary activity / Product lines

- Flow Cytometry

- Centrifugation

- Particle Counting and Characterization

- Liquid Handling and Robotics

- Nucleic Acid Sample Preparation

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.