This article shows how MET ONE Instruments’ HHPC 6+ handheld particle counter is used to classify an ISO Class 5 clean room and the related ISO Class 7 gowning room. References have been made to the ISO 14644-1 standard with respect to locations selected, sample size, limits and calculations required to establish the conformity status of the clean zone to ISO 14644-1 Class 5 standard

Image credt: Beckman Coulter

Background

A small ISO Class 5 clean room facility was set up by a precision engineering manufacturer to provide a controlled setting for assembly of customized optical assemblies. An ISO Class 7 gowning area is used to access the main ISO Class 5 clean room. In line with their ISO 9000 quality control policies, the QA team proposed that both the gowning and assembly zones should be certified every six months when the areas are in "at rest" condition.

As part of a continual quality enhancement initiative, the team also planned to carry out particle analyses during the optical assembly operations that involve measurement of air particle counts at the sampling site using a handheld air particle counter.

The QA manager planned to carry out the routine certification process in-house so as to eliminate the costs which would otherwise increase if this process was outsourced to third parties. Also, since the clean room was very small, a portable particle counter was found to be a suitable solution.

The QA group finally selected the MET ONE model HHPC 6+ particle counter, which makes it easy to transfer data to a computer through USB, without the additional software. The instrument also comes with an on-screen graphical trending function which was found to be useful in particle profiling studies.

The Cleanroom

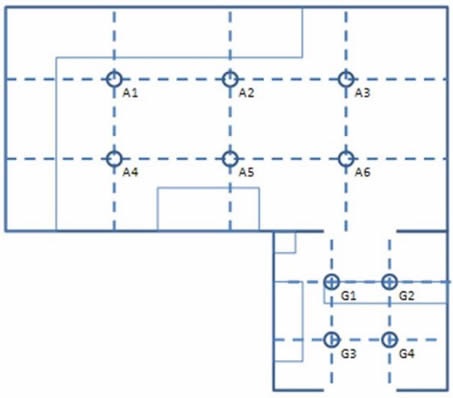

The initial task was to assess the clean room and establish both sample volumes and sample locations in order to conform to the ISO 14644 "Clean rooms and associated controlled environments" Part 1 and 2 standards. Then, a floor plan was drawn (Figure 1) after the size of the clean room was evaluated.

Figure 1. The Cleanroom Layout. Image credt: Beckman Coulter

Classification Frequency

As per ISO 14644 specifications, there should be a maximum interval of time between reclassification, as 6 months for classifications below or equal to ISO Class 5, and 1 year for clean rooms greater than ISO Class 5. Conversely, classification can be performed either "in operation" or “at rest” condition. The QA manager opted to certify "at rest" condition every six months in proportion to the ISO 14644-1 and -2 standard.

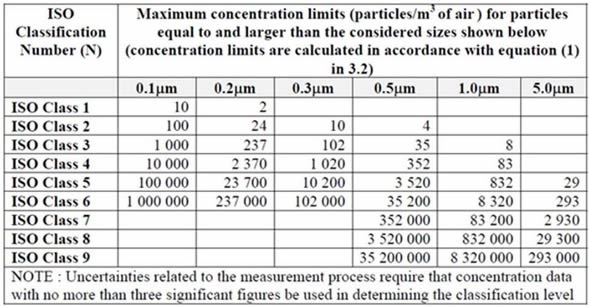

Choosing Particle Sizes

As per ISO 14644-1 standards, based on the target cleanliness class, clean rooms must be classified within a range of particle sizes. ISO Class 5 clean rooms and ISO Class 7 clean rooms can be classified from 0.1µm to 5.0µm and from 0.5µm to 5.0µm, respectively. The QA manager finally selected 0.5µm as the classification size for both the gowning and assembly areas, given that optical assemblies were susceptible to particles down to 0.5µm.

Establishing Sample Locations

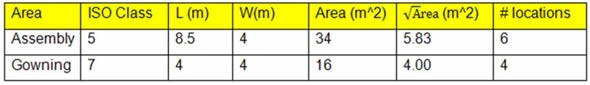

ISO 14644-1 specifies the least number of locations to be sampled for particles depending upon the dimension of the area to be classified. The formula is given below:

Where A is the area of the clean room in square meters, and Nl is the number of locations.

The computed result that is not an integer should be rounded up to the subsequent whole number (Figure 2).

Figure 2. Calculating the number of sample locations. Image credt: Beckman Coulter

In line with the standard accepted practice, the preferred number of sampling locations was distributed uniformly within the clean areas to be monitored (Figure 3).

Figure 3. Distributing sample locations within the clean zones. Image credt: Beckman Coulter

Establishing Sample Air Volume

ISO 14644-1 specifies the least sample volume as that volume where the least number of 20 particles would be identified, provided the concentration of particles for the largest size of particles were at the class limit for the selected ISO Class. The formula is given below:

Where Vs is the minimum single sample volume for each location in liters, and Cn,m is the class limit for the largest particle size (n) defined for the class limit (m).

The QA manager opted to classify at a single size, 0.5µm.

Calculating Required Sample Size

With reference to Figure 4:

- Gowning area (ISO Class 7) C0.5,7 = 352000

- Assembly area(ISO Class 5) C0.5,5 = 3520

- Assembly area minimum sample volume per location: Vs = 20/3520 x 1000 and Vs = 5.68L

- Gowning area minimum sample volume per location Vs = 20/3520000 x 1000 and Vs = 0.0568L

Figure 4. Selected Airborne Particulate Cleanliness Classes for Cleanrooms and Clean Zones. Image credt: Beckman Coulter

It should be noted that ISO 14644-1 standard specifies lower limits on minimum volumes sampled at each location to be no less than 2L and also specifies minimum sample period to be 1 min. The MET ONE HHPC 6+ portable particle counter offers a sampling flow rate of 2.83L/min. Thus, the estimated requirement for the assembly zone is Vs = 5.68L at 2.83L/min needs a nominal sample time of 2.0 min for each location.

The estimated requirement for the gowning zone is Vs = 0.0568L at 2.83L/min needs a sample time of 0.02 min for each location. Again it should be noted that in the case of the gowning zone, minimum sample period of 1 minute, as defined by the ISO 14644-1 standard, will apply. Although a single was needed at each four locations in the gowning zone, two samples were taken at each location as taken for the assembly zone to ensure consistency.

Sampling Plan Summary

- Gowning area (ISO Class 7) 2 x 1 minute samples at each of 4 locations

- Assembly area(ISO Class 5) 2 x 1 minute samples at each of 6 locations

- Frequency: Conducted every six months

Setting up the MET ONE HHPC 6+ Particle Counter

The MET ONE HHPC 6+ handheld particle counter can be easily setup for the classification of clean rooms. Initially, channel size 0.5µm is chosen with data presented as cumulative counts normalized to cubic meters. Then, after setting the sample method for 2 x 1 min, particle counts were taken for each of the six locations in the assembly zone and each of the four locations in the gowning zone.

Analysis of Results

Statistical calculations for studying the particle count data are provided by Annex C of ISO 14644-1. This is in the form of a Students-t test where the 95% upper confidence limit (UCL) is measured and compared to the class limit. The formulas are specified in Annex F and can be transferred to a spreadsheet (Figure 5).

Figure 5. Statistical calculations for analyzing the particle count data. Image credt: Beckman Coulter

Conclusion

The assembly and the gowning room area results create 95% Upper Confidence Intervals that are well below the ISO Class limits, and hence these zones were certified as ISO Class 5 and ISO Class 7, respectively.

About Beckman Coulter

About Beckman Coulter

Beckman Coulter develops, manufactures and markets products that simplify, automate and innovate complex biomedical tests. More than a quarter of a million Beckman Coulter instruments operate in laboratories around the world, supplying critical information for improving patient health and reducing the cost of care.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.