SPECTROstar Nano and Brewing and Distilling Analytical Services, LLC, have been key to advancing the quality of the testing and analysis of alcohol beverages over recent years. A reliable test to combat counterfeiters and ensure that distilled spirits are original has been developed by the proprietor of Brewing and Distilling Analytical Service, Gary Spedding, Ph.D. Using this test, a distinct “fingerprint” spectral curve can be observed in the UV/Vis absorbance spectra of the original spirit, which it is not possible to replicate in diluted or counterfeit spirits. The SPECTROstar Nano is capable of measurements in both microplate and cuvette form, thereby offering flexibility, speed and consistency in measurements.

White and aged spirits are considered the main classes of distilled spirits. As spirits age in the wood, they acquire tannins, sugars, other complex biochemical compounds and color and undergo significant chemical reactions. The profile of the spirit itself is then modified in ways that are complex and largely unresolved. UV-visible sample scanning may be used to detect or follow changes as the spirits age and pick up components.

The spectra of a large number of samples can be determined simultaneously in a quick and accurate manner using the SPECTROstar Nano microplate reader. The integrated spectrometer can record spectra over time and overlay plots of all measurements can be created using the MARS data evaluation software, making near-real-time evaluation of distilled spirit quality possible.

Principle of Assay

A key consideration while evaluating more complex or darker colored liquors and spirits is that they need to be undiluted and volumes kept small, to allow for very short path-lengths. The MARS software includes a data library of the specific style and brand fingerprints for authentication purposes. The newly obtained sample data is then compared with the relevant data set, to determine the quality of the sample. The range of spectra recorded is usually around 250 to 400nm and a key feature for a number of spirits is a broad band centered around 280nm that changes amplitude depending on the type of spirit and brand.

Based on blending, process, aging and additives, distinct fingerprints are characterized both from within the same style and with differences in brand. Eventually, it is possible to generate a product fingerprint library that can be used to help maintain product quality and detect adulteration of the product.

Materials and Methods

The instruments used for the experiment include:

- UV instrument 96-well plates (Costar)

- SPECTROstar Nano (BMG LABTECH)

Figure 1. BMG LABTECH’s UV-Vis absorbance microplate reader SPECTROstar Nano. Image credit: BMG Labtech.

Being careful not to introduce any bubbles, pipetting of the indicated spirit samples (Figures 2-4) was performed into microplates in replicates. Low volumes (100ml) were used and the plates analyzed on a SPECTROstar Nano.

Instrument Settings

The instrument settings are listed below:

- Measurement mode: Endpoint

- Wavelength Settings: Spectra

- Wavelength Range: 220-1000nm

- Scan Resolution: 2nm

- Path Length Correction: Off

Results and Discussion

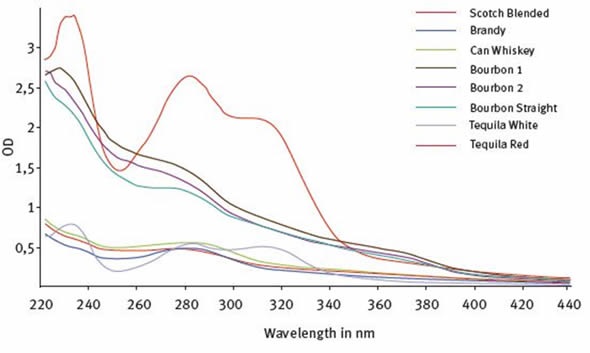

Figure 2 shows the typical spectral profiles for a range of distilled spirit types. The spirits ranged from white colored silver tequila through to aged tequila and darker colored spirits such as Scotch whisky, Canadian whisky and three Bourbon whisky brands. Therefore, it is observed that there are broad spirit class distinctions and subtle but unique distinctions between the same kinds of spirit. The distiller is often interested in the desirable aging changes linked to maturation in the wood.

Figure 2. UV-Visible fingerprint profiles of white and colored classes of distilled spirits. Image credit: BMG Labtech.

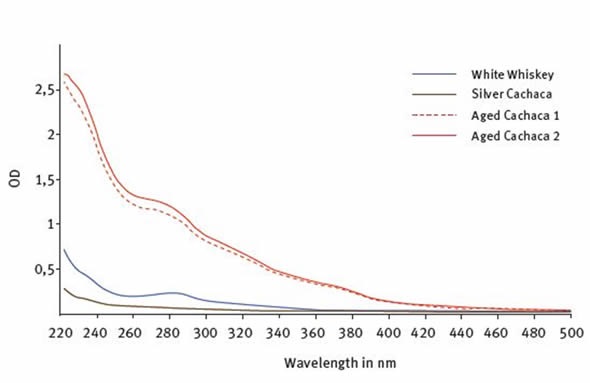

Figure 3. UV-Visible fingerprint profiles of a white whiskey and un-aged and an aged Cachaça (cane sugar spirit). Image credit: BMG Labtech.

Although this a complex subject, it is important to note that the rapid monitoring of profile changes is possible through selected timings and spectral analysis (Figure 3). A typical low amplitude, un-aged profile is shown by an un-aged cachaça and a white whiskey. A classic wood aged product is also produced by the same distillery for the cachaça and shows the enhanced amplitude profile typical of such wood aging and is also distinctive for the brand. In addition, the fingerprint is valid across batches, as demonstrated by the two aged profiles.

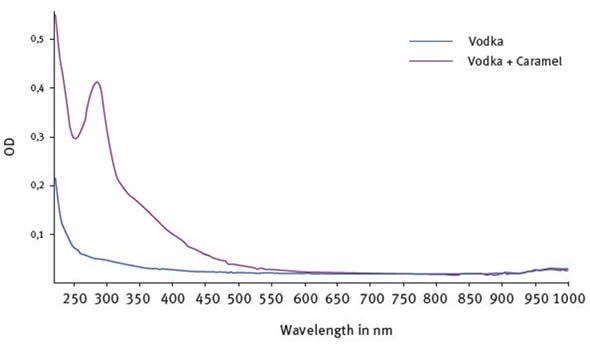

The profiles are sufficiently similar to warrant the finding that the UV-visible scanning is generally a valid technique for detecting and authenticating brands. In the case of some spirits, a spirit-grade caramel can be added. Using spectroscopy (Figure 4), it is possible to determine the caramel quality. This data is beneficial in cases where the addition of caramel has been declared, or when caramel addition is suspected but not expected.

Figure 4. UV-Visible fingerprint profiles of a white spirit “as is” and after the addition of a spirit grade caramel. Image credit: BMG Labtech.

Conclusion

The effectiveness of the SPECTROstar Nano in quality control testing of distilled beverages has been discussed in this article. It can be used for adulterant and counterfeit studies and for brand authentication. The SPECTROstar Nano can also be used for handling multiple samples simultaneously and can return data on a range of samples within minutes. There is no need to prepare or dilute samples or to switch path-length devices and no blanks are required, thereby enabling rapid, accurate and effective data collection. The sample size can be as little as 100µl and replicate analyses are easy to perform in the multi-well microplate format.

About BMG Labtech

BMG LABTECH has been committed to producing microplate readers for more than twenty years. By focusing on the needs of the scientific community, the company’s innovative microplate readers have earned the company the reputation of being a technology leader in the field.

BMG LABTECH has developed a wide range of dedicated and multi-mode microplate readers for life sciences applications and high-throughput screening.

All BMG LABTECH microplate readers are "Made in Germany" and are conceived, developed, assembled, and tested entirely at our headquarters in Germany.

Since our establishment in Offenburg, Germany in 1989, BMG LABTECH has expanded to offer a worldwide sales and support network with offices in the USA, UK, Australia, Japan and France. Our subsidiaries, regional offices and distributors are committed to bringing you innovative microplate reader technology with the quality and reliability you expect from a German company.

Our staff includes engineers and scientists from the fields of biology, biochemistry, analytical chemistry, and physics.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.