Sponsored Content by SartoriusReviewed by Alex SmithJun 30 2022

Extensively found and used in all kinds of laboratories, mechanical pipettes are durable tools. They are typically used for several hours a day, therefore, ergonomics and personal preferences – including handling comfort – are crucial selection criteria.

Other relevant factors such as the application, laboratory workflow, physical properties of the sample, required volume ranges and requirements for accuracy and precision also must be taken into account when searching for the best pipette for the job.

Image Credit: Sartorius

Accuracy and precision

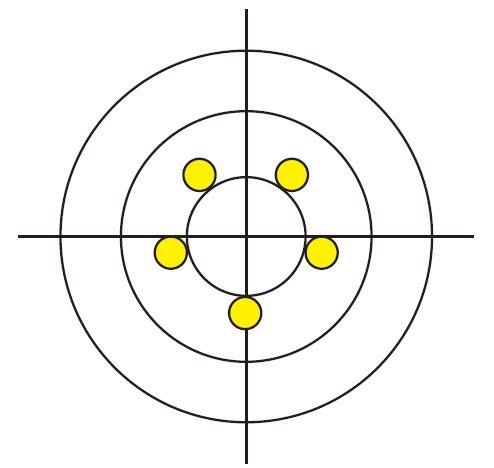

Accuracy and precision are among the two major aspects when selecting a good pipette. Accuracy means that the volume delivered meets the volume set. Precision is an expression of the proximity of several pipetting results. Here are some examples:

Accurate, but not precise

The result is accurate but not precise: The mean volume is in accordance with the set volume, but the individual pipetting results differ from each other.

Image Credit: Sartorius

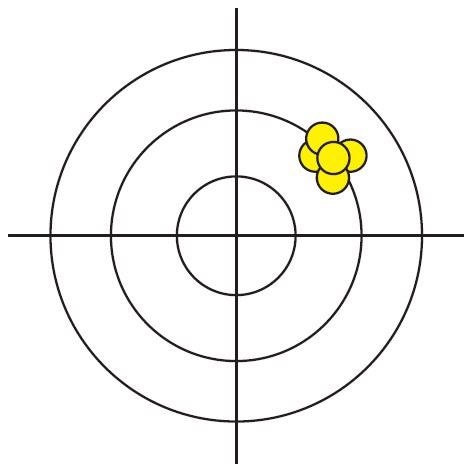

Precise, but not accurate

The result is precise but not accurate: There is only a small variation between pipetting results; however, the mean volume does not correlate with the set volume.

Image Credit: Sartorius

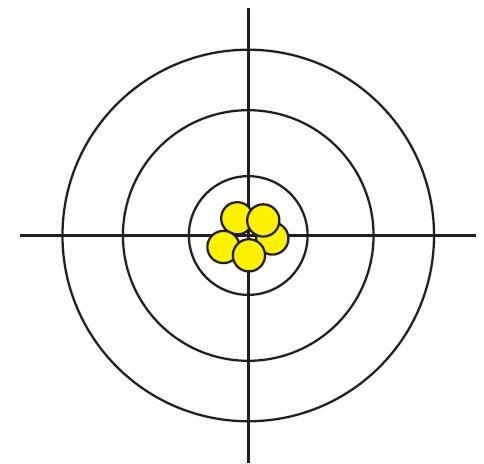

Precise and accurate

The result is accurate and precise: The mean volume is equal to the set volume; there is only a slight variation between pipetting results.

Image Credit: Sartorius

The terms accuracy and precision are exhibited in the technical specifications of the pipette as systematic error % (inaccuracy %) and random error % (imprecision %). it should be noted that the specifications are only valid when the manufacturer’s own pipette tips are used.

The best accuracy can be achieved by using a high-quality, professionally calibrated and well-maintained pipette with the necessary high-quality tips. On the other hand, precision is by and large influenced by pipetting experience and excellent laboratory practices, such as suitable pipetting angles, a consistent pipetting rhythm and optimal pipetting speed.

To ensure the highest level of accuracy is achieved, users should select the smallest volume pipette with the capacity to handle the volume in question. This is vital because the accuracy of pipetting decreases when the dispensed volume nears the pipette’s minimum capacity.

For instance, using a 1 ml pipette when dispensing 10 μl of liquid would lead to poor accuracy, a 300 μl pipette would be better suited, and a 10 μl pipette is even better.

Furthermore, to ensure good pipetting results are achieved, it is crucial to select a pipette with low pipetting, tip-loading and tip-ejection forces.

High forces can lead to fatigue in the arm and hand muscles more easily, creating the risk of inadequate results, particularly in long pipetting series. It is advised that users keep an eye out for the following features, all of which influence the performance and reliability of pipetting results:

- Color coding of the pipette or pipette caps – this helps users select the correct tip for the pipette.

- Easy calibration for different kinds of liquids. It is also beneficial if settings can be saved for later use.

- Volume adjustment locking – This feature helps to mitigate accidental volume changes during pipetting. Special attention should also be paid to the reliability, ergonomics and intuitiveness of the mechanism.

Ergonomics

Pipetting is one of the most frequently performed tasks in a laboratory on a day-to-day basis. Studies have linked consistent pipetting with a greater risk of upper body musculoskeletal disorder, and over 40% of lab professionals can be plagued by pipetting-related disorders.*

As well as causing discomfort, hand or arm injuries may restrict performance levels and may cause a knock-on effect where accuracy, precision and the reliability of results is concerned. For the best possible ergonomics, it is crucial to pay close attention to the following qualities when selecting a pipette:

Grip design and balance

The fit between the pipette and the hand should be comfortable, and the finger support should make holding the pipette effortless. Furthermore, a well-balanced pipette with the mass center close to the palm offers stability that considerably reduces hand muscle strain and wrist torque.

Required pipetting force

The risk of RSI is increased when pipetting force increases. Additionally, it causes a reduction in the accuracy and precision of long pipetting series. The force typically required to move the plunger to the first stop should be between 3 and 15 N. Yet, the force needed to press the plunger to the second stop can reach up to 40 N.

A simple test is possible to compare the pipetting forces of two pipettes by pressing the plungers against each other. The plunger demonstrating the lower pipetting force will move first.

Suitability for right and left-handed users

The pipette should be comfortable for both right and left-handed users to use. All operations should be equally functional from both directions. Moreover, the display should be easy-to-read regardless of direction.

Tip ejection forces

Tip ejection generally requires more force than pipetting. The high tip ejection forces of mechanical pipettes can pose an injury risk, specifically where repetitious pipetting is performed. Typical tip ejection forces range from 15 to 30 N.

Tip loading

Next to tip ejection, tip loading demands the most force throughout the pipetting process. The tip loading force is the force needed to firmly attach the tip to the pipette. Poorly fitting tips require tapping, rocking or even manually tightening to ensure proper sealing. The force can be limited by using properly fitting tips.

Volume display

To prevent the pipette from being held in an awkward position, the volume should be easy-to-read during normal pipetting. Also, the larger the numbers, the easier they are to read.

Volume adjustment

Adjusting the pipetting volume should be convenient and ergonomic. To prevent any unnecessary strain on the thumb, it should be easy to adjust the volume with both hands – one holding the pipette in place while the other rotates the adjustment wheel.

Weight and length

A pipette is more ergonomic if it is lighter and shorter.

*Bjorksten, M. G., B. Almby, and E., S. Jansson. 1994, Fredriksson, K. 1995

Preventing contamination

To prevent the spread of aerosols or drops of a sample when ejecting the tip, make sure a pipette with gentle tip ejection has been selected. When the tip is gently ejected, the liquid droplets or aerosols that are left behind are much less likely to disperse over a large area.

For rapid, convenient decontamination procedures, select a mechanical pipette that can be autoclaved without disassembly - this is also applicable to multichannel models. Pipettes should be chosen on the basis that they offer the possibility to use a filter on the tip cone.

Tip-cone filters prevent aerosols and fluids from entering the internal components of the pipette. They are also a thrifty and effective way to avoid sample contamination. Alternatively, filtered pipette tips can be utilized in an application.

Single or multichannel pipette?

Single-channel pipettes are the workhorses of liquid handling. They come in a range of adjustable and fixed-volume models. Adjustable-volume pipettes mean the dispensed volume can be changed as necessary, whereas fixed-volume pipettes always dispense the same quantity of liquid each and every time.

Fixed-volume pipettes prevent dispensing errors brought on by incorrect volume selection. They are well-suited to applications with a constant liquid transfer volume as well as being perfect for beginners and non-certified technicians.

Here are the most important points to consider when selecting a multichannel pipette:

- Check the position of the lower part of the pipette and that it is possible to adjust it across 360 degrees to ensure ergonomic pipetting.

- Check that the tips can be easily ejected.

- Make sure that the pipette offers rapid, secure and simultaneous tip-loading for all tips. It should be possible to evenly mount the tips without too much force.

Image Credit: Sartorius

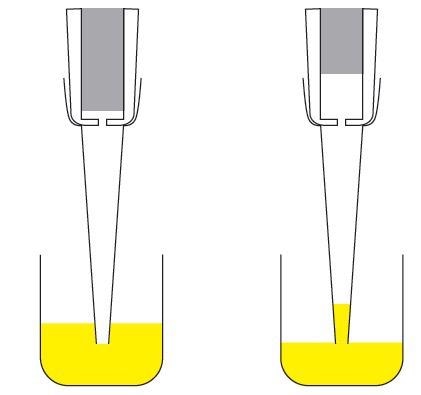

Air or positive displacement pipette?

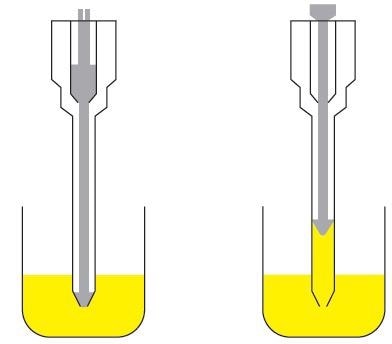

There are two kinds of mechanical, piston-operated pipettes: air displacement and positive displacement pipettes.

Air displacement pipettes, which have been developed with general laboratory work and aqueous samples in mind, have an air column between the piston and the liquid. Most pipetting work performed in laboratories uses this type of pipette.

How an air displacement pipette works. Image Credit: Sartorius

Positive displacement pipettes have been designed for working with demanding samples such as extremely viscous, volatile, radioactive or corrosive liquids. With this kind of pipette, the piston is in immediate contact with the liquid, lowering the risk of contamination close to zero.

Positive displacement pipettes necessitate the use of special tips, therefore, this kind of pipetting is more expensive than air displacement pipetting.

How a positive displacement pipette works. Image Credit: Sartorius

Calibration and maintenance

All pipettes require routine maintenance to guarantee results that are reliable as well as to ensure maximum instrument lifetime. When selecting a pipette, it is crucial to consider the service aspects.

If the user needs to conduct calibration, it is essential to ensure that this is possible and that it is relatively simple to do. If the user needs to clean the pipette, it should be easy to disassemble and should have as few removable parts as feasible.

The pipettes that are easy to clean typically have three removable parts and can be disassembled without the need for tools. If users plan on conducting external calibration and maintenance services, it is essential to find out the location of the closest service center, as well as the cost, quality and speed of their services.

A disassembled mechanical pipette. Image Credit: Sartorius

Lubricating a mechanical pipette. Image Credit: Sartorius

About Sartorius

Sartorius is a leading international pharmaceutical and laboratory equipment supplier. With our innovative products and services, we are helping our customers across the entire globe to implement their complex and quality-critical biomanufacturing and laboratory processes reliably and economically.

The Group companies are united under the roof of Sartorius AG, which is listed on the Frankfurt Stock Exchange and holds the majority stake in Sartorius Stedim Biotech S.A. Quoted on the Paris Stock Exchange, this subgroup is comprised mainly of the Bioprocess Solutions Division.

Innovative technologies enable medical progress

A growing number of medications are biopharmaceuticals. These are produced using living cells in complex, lengthy and expensive procedures. The Bioprocess Solutions Division provides the essential products and technologies to accomplish this.

In fact, Sartorius has been pioneering and setting the standards for single-use products that are currently used throughout all biopharmaceutical manufacturing processes.

Making lab life easier

Lab work is complex and demanding: Despite repetitive analytical routines, lab staff must perform each step in a highly concentrated and careful way for accurate results.

The Lab Products and Services Division helps lab personnel excel because its products, such as laboratory balances, pipettes and lab consumables, minimize human error, simplify workflows and reduce physical workloads.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.