Creams are applied on the skin surface of different body parts for various intended purposes. Various personal care products, cosmetics or pharmaceuticals are available as creams. While some of the creams used as dosage forms are intended for the topical absorption of the active ingredients into different skin layers, including the epidermis or dermis, most creams also help normalize the humidity of the skin.

Traditional Methods Used to Determine the Moisture Content in Creams

Due to their widespread use, creams are subjected to stringent quality control. Due to the importance of water in the texture, feel and moistening characteristics of creams, determination of water content is one of the most important parameters in the quality control of creams. KF titration is the traditional method generally used to determine water content.

In the KF titration method, the creams need to be dissolved in absolute methanol by heating them in an ultrasonic bath. Due to presence of certain ingredients, solubilizing certain creams can be challenging. In these cases, mixtures of solvents, which include methanol, chloroform, decanol along with other solubilizers may be required prior to titration with Karl Fischer reagent to determine to moisture content.

NIRS as an Alternative Method to KF Titration

A rapid, non-destructive analytical method, Near-infrared spectroscopy (NIRS) can be used as an alternative to KF titration method in the routine quality control analysis of creams. The NIRS method requires no dissolution of creams in solvents and therefore requires no sample preparation. The samples can be analyzed in a few seconds once the analytical protocol is developed.

Experimental Set Up

To test the validity of NIRS in determining the water content in the creams, the water content in 42 commercially available creams were analyzed and the results were compared between the KF titration to the NIRS. The moisture content in the 42 creams were first determined by KF titration procedure in triplicates and were found to be between 60% to 80%. These initial values were used to develop the NIRS model.

A 0.5 gram of each cream were applied on the NIRS Slurry Cup of the Metrohm NIRS DS2500 Analyzer and was pressed with the NIRS Diffuse Reflectors, Gold 1 mm to analyze the creams in transflection mode. In this mode, the reflected light that passes through the sample via the gold reflector back is analyzed by the detector.

The spectra of the creams tested at wavelengths ranging from 400 nm to 2500 nm were obtained. The gold stamp and the Slurry Cup were carefully cleaned with dry paper towels between each use. Vision Air 2.0 Complete software was used for acquiring and management of data as well as for the development of the quantification method. The quantitative method development was done using the Vision chemometric software.

Figure 1. Moisturizing creams used in this study.

Table 1. Used equipment and software.

| Equipment |

Metrohm code |

| NIRS DS2500 Analyzer |

2.922.0010 |

| NIRS Slurry Cup |

6.7490.430 |

| NIRS Diffuse Reflectors, Gold 1 mm |

6.7420.000 |

| Vision Air 2.0 Complete |

6.6072.208 |

Figure 2. The Metrohm NIRS DS2500 Analyzer was used for spectral data acquisition over the full range from 400 nm to 2500 nm (left) and the used NIRS Slurry Cup and 1mm Gold Diffuse Reflector (right).

Method Development

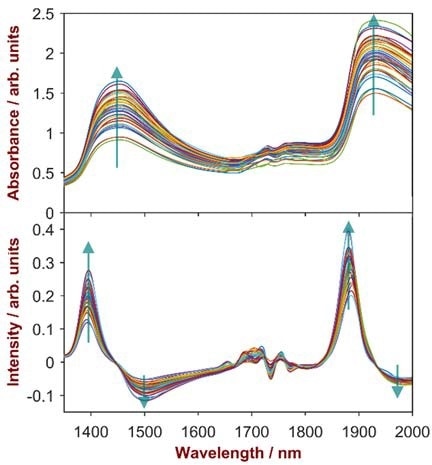

The analysis results obtained by both the methods were used in the development of subsequent method. The spectra obtained were pre-treated using a Detrend function (2nd order polynomial baseline correction) in along with a 1st derivative. The multivariate regression method Partial Least Squares Regression (PLS) was carried out over the spectral regions at 1350 – 1500 nm and 1800 – 2000 nm both of which represent the two most prominent water bands. The spectral variations arising due to concentration changes of moisture were observed.

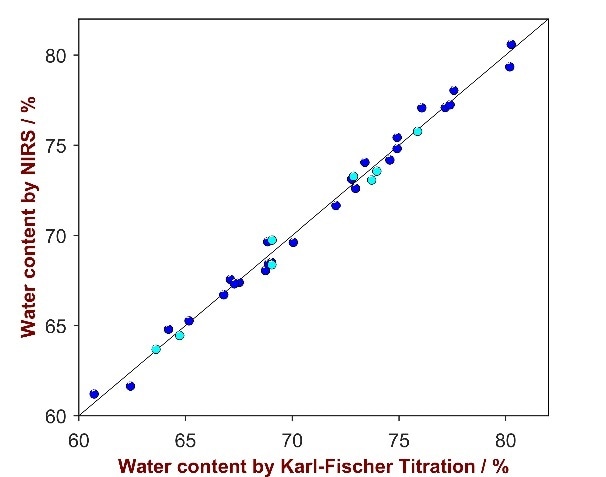

Three of the samples which appeared more wax like than creams were identified as outliers and the rest of the samples were separated into a calibration set, consisting of 31 samples and a validation set, consisting of 8 samples.

Figure 3. The raw spectra (upper trace) were pre-treated using a Detrend function with a subsequent 1st derivative (lower trace). The arrows indicate the trend to higher water concentration.

Results

Because of the varying sample matrices, the model was fitted using 4 factors. The results from the analysis of the revealed a Standard Error of Calibration of 0.565%, Standard Error of Cross Validation of 0.745% and Standard Error of Prediction of 0.819%, showing that the model is robust and reliable. The defined validation set was used for external validation, yielding.

Figure 4. Correlation plot of the moisture concentration determined by Karl- Fischer titration and predicted by NIRS. The blue marks stand for samples used in the calibration set, the turquois marks are samples used in the validation set.

Table 2. Results of the quantitative method for water content in skin creams.

| . |

. |

| Regression model |

PLS with 4 factors |

| Pre-treatment |

Detrend, 2nd order polynomial,

1st derivative,

10 nm segment size |

| Wavelength range |

1350–1550 nm

1800-2000 nm |

| R2 |

0.992 |

| SEC |

0.565% |

| SECV |

0.745% |

| SEP |

0.819% |

Conclusion

The results here demonstrate that the NIRS is excellent alternative to KF titration in the determination of water content as part of the out-of- specification analysis and final product quality control of creams. Vis-NIR spectroscopy offers several unique advantages over traditional analysis methods, which include the generation of rapid and reliable results, no sample preparation or use of any toxic chemicals. Most importantly, this method does not generate any waste and the accessories can be easily cleaned before every subsequent use.

References

1. KF Application Note No. K-11, Water in moisturizing creams (cosmetic products)

About Metrohm

At Metrohm is one of the world’s most trusted manufacturers of high-precision instruments for chemical analysis. Metrohm was founded in 1943 by engineer Bertold Suhner in Herisau, Switzerland. Today, Metrohm is represented in 120 countries by subsidiaries and exclusive distributors. The global Metrohm Group also includes the Dutch companies Metrohm Applikon and Metrohm Autolab, manufacturers of online analyzers and instruments for electrochemical research, respectively. Recently, the Metrohm Group was joined by Metrohm Raman, a leading manufacturer of handheld Raman spectrometers.

Metrohm is the global market leader in analytical instruments for titration. Instruments for ion chromatography, voltammetry, conductivity, and stability measurement make the Metrohm portfolio for ion analysis complete. Instruments for Near-infrared and Raman spectroscopy are another, strongly growing segment of the Metrohm portfolio.

Metrohm is a problem solver, both in the laboratory and within the industrial process. To this end, the company offers their customers complete solutions, including dedicated analytical instrumentation as well as comprehensive application know-how. More than 30% of the company’s employees at the Metrohm international headquarters in Herisau work in R&D.

Metrohm has been owned 100% by the non-profit Metrohm Foundation since 1982. The Metrohm Foundation, which does not exert any influence on the company’s business operations, sponsors gifted students in the natural sciences, supports charitable and philanthropic purposes and, above all, ensures the independence of the company.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.